Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

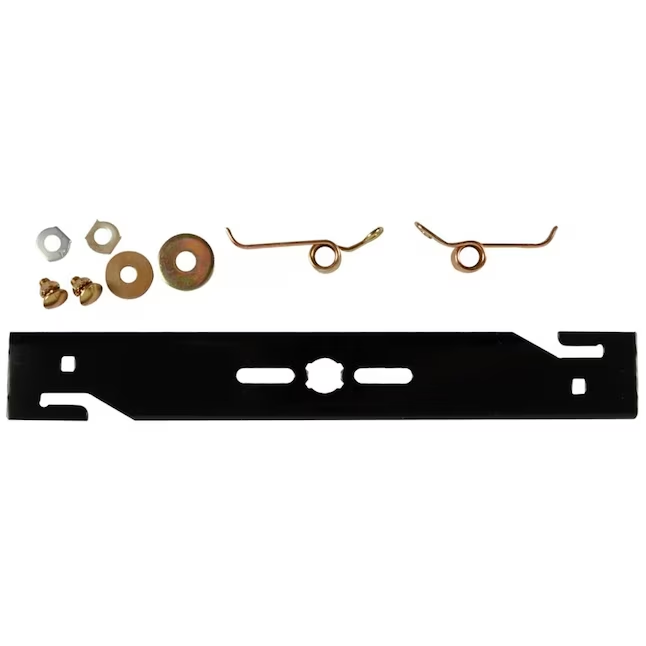

How does a dethatching blade work to remove thatch effectively?

A dethatching blade is a specialized tool designed to effectively remove thatch from lawns. Here’s a detailed explanation of how a dethatching blade works to remove thatch effectively:

A dethatching blade typically consists of multiple sharp, rigid tines or blades that are attached to a rotating shaft. When the blade is attached to a lawn mower or a dethatcher machine, the rotation of the blade allows the tines to penetrate the thatch layer and lift it from the surface of the soil.

1. Tine Penetration:

– As the dethatching blade rotates, the sharp tines or blades penetrate the thatch layer, which is the layer of dead grass, debris, and organic matter that accumulates between the grass blades and the soil surface.

– The tines are designed to reach deep enough to effectively lift the thatch without causing excessive damage to the healthy grass or the underlying soil.

2. Thatch Lifting:

– As the tines move through the thatch layer, they lift the accumulated debris and dead grass from the surface of the soil.

– The lifting action breaks up the thatch into smaller pieces, making it easier to remove and allowing better access to air, water, and nutrients for the underlying grass roots.

3. Thatch Removal:

– Once the thatch is lifted, it is either expelled from the machine or left on the surface of the lawn to be collected manually or through subsequent mowing and raking.

– Some dethatching blades may have additional features, such as a collection bag or a rear-mounted rake, to facilitate the removal of the lifted thatch.

4. Benefits of Dethatching:

– Dethatching with a dethatching blade offers several benefits for the health and appearance of the lawn:

– Improved Air Circulation: Removing the thatch layer allows better air circulation, reducing the risk of fungal diseases and promoting a healthier lawn.

– Enhanced Water Penetration: Thatch removal improves water penetration, preventing water runoff and ensuring that water reaches the grass roots more effectively.

– Increased Nutrient Absorption: Removing thatch allows nutrients to reach the grass roots, promoting healthier growth and greener grass.

– Improved Overall Lawn Health: By removing thatch, dethatching blades can help rejuvenate the lawn, resulting in a thicker, lusher, and more vibrant turf.

It’s important to note that the effectiveness of a dethatching blade depends on various factors such as the condition and thickness of the thatch layer, the type of grass, and the dethatching technique applied. It’s recommended to follow the manufacturer’s instructions and consider consulting with lawn care professionals for specific guidance on using a dethatching blade effectively.

What types of lawns require the use of a dethatching blade?

Not all lawns require the use of a dethatching blade, as the need for dethatching depends on the specific grass type and the extent of thatch buildup. Here’s a detailed explanation of the types of lawns that may require the use of a dethatching blade:

1. Lawns with Excessive Thatch:

– Lawns that have developed a thick layer of thatch, typically more than half an inch in depth, may require dethatching. Thatch buildup can occur due to factors such as infrequent mowing, over-fertilization, over-watering, or poor soil conditions.

– Thick thatch prevents air, water, and nutrients from reaching the grassroots, leading to poor lawn health, reduced vigor, and increased susceptibility to diseases and pests.

– Dethatching helps remove the excessive thatch layer, allowing the grass to breathe, absorb water and nutrients more effectively, and promote healthy growth.

2. Lawns with Cool-Season Grasses:

– Cool-season grasses, such as Kentucky bluegrass, perennial ryegrass, and tall fescue, are more prone to thatch buildup compared to warm-season grasses.

– These grasses tend to produce more above-ground stolons and rhizomes, which can contribute to the accumulation of thatch over time.

– Regular dethatching can be beneficial for lawns with cool-season grasses to maintain a healthy thatch level and prevent excessive buildup.

3. Lawns with Warm-Season Grasses:

– Warm-season grasses, such as Bermuda grass, Zoysia grass, and St. Augustine grass, generally have a lower tendency to develop thatch compared to cool-season grasses.

– However, in certain conditions, such as heavy fertilization or excessive irrigation, warm-season grasses can also accumulate thatch.

– While dethatching may not be a routine requirement for warm-season lawns, occasional dethatching can help maintain optimal lawn health, particularly if thatch buildup becomes problematic.

4. Lawns with Compacted Soil:

– Lawns with compacted soil can experience reduced water infiltration and poor air circulation, which can contribute to thatch accumulation.

– Compacted soil can impede the natural breakdown of organic matter, leading to an increased buildup of thatch.

– Dethatching, combined with aeration to alleviate soil compaction, can be beneficial for lawns with compacted soil, regardless of the grass type.

It is important to note that not all lawns require dethatching, and the decision to use a dethatching blade should be based on the specific conditions of the lawn. It is recommended to consult with a lawn care professional or a local cooperative extension office to determine if dethatching is necessary for your specific lawn type and condition.

editor by CX 2024-01-17

China Custom Lawn Punching Machine Lawn Aerator Small Garden Tiller Small Cultivator

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

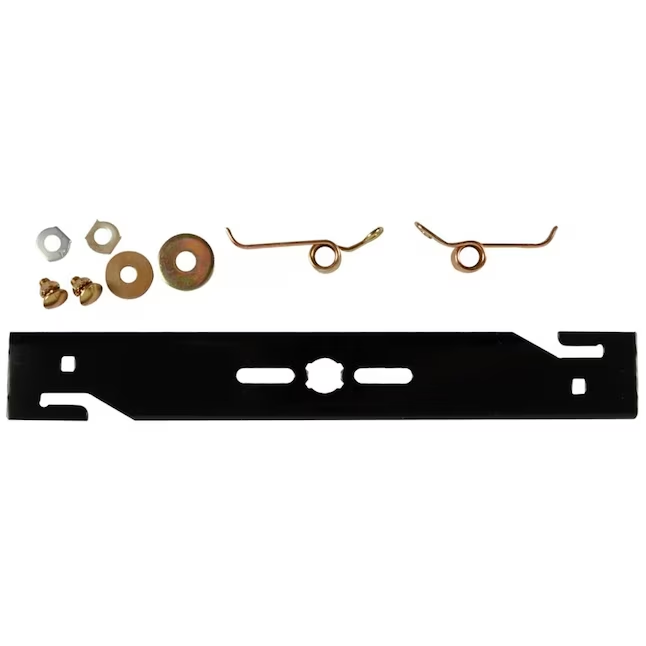

How does a dethatching blade work to remove thatch effectively?

A dethatching blade is a specialized tool designed to effectively remove thatch from lawns. Here’s a detailed explanation of how a dethatching blade works to remove thatch effectively:

A dethatching blade typically consists of multiple sharp, rigid tines or blades that are attached to a rotating shaft. When the blade is attached to a lawn mower or a dethatcher machine, the rotation of the blade allows the tines to penetrate the thatch layer and lift it from the surface of the soil.

1. Tine Penetration:

– As the dethatching blade rotates, the sharp tines or blades penetrate the thatch layer, which is the layer of dead grass, debris, and organic matter that accumulates between the grass blades and the soil surface.

– The tines are designed to reach deep enough to effectively lift the thatch without causing excessive damage to the healthy grass or the underlying soil.

2. Thatch Lifting:

– As the tines move through the thatch layer, they lift the accumulated debris and dead grass from the surface of the soil.

– The lifting action breaks up the thatch into smaller pieces, making it easier to remove and allowing better access to air, water, and nutrients for the underlying grass roots.

3. Thatch Removal:

– Once the thatch is lifted, it is either expelled from the machine or left on the surface of the lawn to be collected manually or through subsequent mowing and raking.

– Some dethatching blades may have additional features, such as a collection bag or a rear-mounted rake, to facilitate the removal of the lifted thatch.

4. Benefits of Dethatching:

– Dethatching with a dethatching blade offers several benefits for the health and appearance of the lawn:

– Improved Air Circulation: Removing the thatch layer allows better air circulation, reducing the risk of fungal diseases and promoting a healthier lawn.

– Enhanced Water Penetration: Thatch removal improves water penetration, preventing water runoff and ensuring that water reaches the grass roots more effectively.

– Increased Nutrient Absorption: Removing thatch allows nutrients to reach the grass roots, promoting healthier growth and greener grass.

– Improved Overall Lawn Health: By removing thatch, dethatching blades can help rejuvenate the lawn, resulting in a thicker, lusher, and more vibrant turf.

It’s important to note that the effectiveness of a dethatching blade depends on various factors such as the condition and thickness of the thatch layer, the type of grass, and the dethatching technique applied. It’s recommended to follow the manufacturer’s instructions and consider consulting with lawn care professionals for specific guidance on using a dethatching blade effectively.

What is a dethatching blade and how is it used?

A dethatching blade is a gardening tool designed to remove thatch from lawns. Thatch is a layer of dead grass, roots, and other organic debris that accumulates between the soil and the healthy grass blades. Here’s a detailed explanation of what a dethatching blade is and how it is used:

1. Definition and Design:

– A dethatching blade is a specialized attachment or accessory that is typically used with a lawnmower or a power rake machine. It consists of a series of sharp, rigid blades or tines arranged in a row.

– The blades or tines of the dethatching blade penetrate the grass and soil, effectively cutting through the thatch layer and lifting it to the surface for removal.

2. Purpose and Benefits:

– The primary purpose of using a dethatching blade is to remove the thatch layer from the lawn. Excessive thatch can prevent air, water, and nutrients from reaching the grassroots, leading to poor lawn health and growth.

– By dethatching the lawn, the grass can better absorb water and nutrients, allowing for improved root development, enhanced overall health, and a more attractive appearance.

3. Usage and Technique:

– Before using a dethatching blade, it is important to ensure that the grass is dry to avoid damaging the turf. Wet grass can be more susceptible to tearing or uprooting.

– The dethatching blade attachment is typically installed on a lawnmower or a power rake machine, following the manufacturer’s instructions.

– When using the dethatching blade, the lawnmower or power rake is moved over the lawn in a systematic pattern, similar to regular mowing, but at a slightly slower pace.

– As the blades or tines rotate or move across the lawn, they cut through the thatch layer, pulling it up and depositing it on the surface in thin strips or clumps.

– After dethatching, the accumulated thatch can be raked or collected and disposed of. Some homeowners may choose to leave a thin layer of thatch behind, depending on the recommendations for their specific grass type.

4. Timing and Frequency:

– Dethatching is typically performed during the growing season when the grass is actively growing and can recover quickly from the process.

– The frequency of dethatching depends on the severity of thatch buildup and the type of grass. In general, it is recommended to dethatch every 1-3 years or as needed.

– Over-dethatching or performing the process too frequently can damage the grass and disrupt the turf’s natural balance.

5. Additional Lawn Care Practices:

– Dethatching is often combined with other lawn care practices, such as aeration and overseeding, to further improve the health and appearance of the lawn.

– Aeration helps alleviate soil compaction and improves the movement of air, water, and nutrients to the grassroots. Overseeding helps introduce new grass varieties and fills in bare patches.

In summary, a dethatching blade is a garden tool used to remove thatch from lawns. It is designed to cut through the thatch layer and lift it to the surface for removal, allowing for improved lawn health and growth.

editor by CX 2024-01-15

China Standard Lawn Punching Machine Lawn Aerator Small Garden Tiller Small Cultivator

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do you maintain and care for a dethatching blade?

Maintaining and caring for a dethatching blade is essential to ensure its optimal performance and longevity. Here’s a detailed explanation of how to maintain and care for a dethatching blade:

1. Clean the Blade:

– After each use, clean the dethatching blade to remove any grass clippings, debris, or thatch buildup.

– Use a brush or a hose to carefully scrub the blade and remove any stuck-on materials.

– Make sure the blade is completely dry before storing it to prevent rust or corrosion.

2. Inspect for Damage:

– Regularly inspect the dethatching blade for any signs of damage, such as bent or dull blades.

– If you notice any damage, replace the damaged parts or the entire blade if necessary.

– Using a damaged blade can result in poor dethatching performance and can potentially harm your lawn.

3. Sharpen the Blades:

– Over time, dethatching blades can become dull, which can affect their cutting efficiency.

– Sharpen the blades of the dethatching blade as needed using a sharpening stone or a file.

– Follow the manufacturer’s instructions or consult a professional if you’re unsure how to properly sharpen the blades.

4. Balance the Blade:

– A balanced dethatching blade is crucial for smooth operation and to prevent damage to your equipment.

– Check the balance of the dethatching blade by suspending it on a nail or a blade balancer.

– If the blade is unbalanced, it may cause excessive vibration or damage to the lawn mower or power rake machine.

– Adjust the balance by removing small amounts of material from the heavier side of the blade until it is properly balanced.

5. Store Properly:

– When the dethatching season is over or if you won’t be using the blade for an extended period, store it properly.

– Clean the blade thoroughly, ensure it is dry, and apply a thin coat of lubricating oil to prevent rust and corrosion.

– Store the dethatching blade in a dry and secure location, away from moisture and direct sunlight.

– Consider using a blade cover or sheath to protect the blade from accidental damage.

By following these maintenance and care practices, you can prolong the lifespan of your dethatching blade and ensure it remains in good working condition. Regular cleaning, inspection, sharpening, balancing, and proper storage will help maintain the blade’s performance, allowing for effective dethatching and a healthier lawn.

Are there any environmentally friendly dethatching blade options?

Yes, there are environmentally friendly dethatching blade options available that can help reduce the environmental impact of lawn care. Here’s a detailed explanation:

1. BioBlades:

– BioBlades are a type of dethatching blade that are designed with the environment in mind.

– These blades are typically made from biodegradable materials or recycled materials, reducing their impact on landfills.

– BioBlades are designed to break down naturally over time, minimizing waste and pollution.

2. Aerating Blades:

– Some dethatching blades come with aerating capabilities, which can be more environmentally friendly.

– Aerating blades have hollow tines or spikes that create small holes in the soil, improving air circulation, water penetration, and nutrient absorption.

– By incorporating aeration into the dethatching process, you can promote healthy soil and reduce the need for chemical fertilizers.

3. Electric-Powered Dethatching Tools:

– Electric-powered dethatching tools, such as electric dethatchers or electric lawn mowers with dethatching attachments, can be considered more environmentally friendly than their gas-powered counterparts.

– Electric tools produce zero emissions during operation, reducing air pollution and greenhouse gas emissions.

– Additionally, electric-powered tools are typically quieter, resulting in less noise pollution.

4. Sustainable Manufacturing:

– Consider dethatching blades from manufacturers that prioritize sustainable manufacturing practices.

– Look for brands that use eco-friendly materials, reduce waste generation, and implement energy-efficient production processes.

– Some manufacturers may also have recycling programs in place for their products, allowing you to dispose of old blades responsibly.

5. Organic Lawn Care Practices:

– In addition to using environmentally friendly dethatching blades, consider adopting organic lawn care practices.

– Regularly aerate and dethatch your lawn to promote healthy soil and reduce the need for chemical treatments.

– Use organic fertilizers, compost, and natural pest control methods to maintain a healthy and eco-friendly lawn.

– By adopting sustainable lawn care practices, you can minimize the environmental impact of your overall lawn care routine.

When looking for environmentally friendly dethatching blade options, consider factors such as the materials used, the manufacturing process, and the overall impact on the environment. Reading product descriptions, labels, and customer reviews can provide valuable insights into the eco-friendliness of different dethatching blades.

Remember that while using environmentally friendly dethatching blades is a step in the right direction, it’s also essential to consider the broader environmental impact of your lawn care practices and explore sustainable approaches to lawn maintenance.

How do you install a dethatching blade on a lawn mower?

Installing a dethatching blade on a lawn mower requires following specific steps to ensure proper attachment and safe operation. Here’s a detailed explanation of how to install a dethatching blade on a lawn mower:

1. Choose the Correct Blade:

– Ensure that you have the appropriate dethatching blade that is compatible with your specific lawn mower model. Refer to the manufacturer’s instructions or consult the mower’s manual to identify the correct blade type and size.

2. Prepare the Mower:

– Before installing the dethatching blade, turn off the lawn mower’s engine and disconnect the spark plug wire to prevent accidental starting.

– If necessary, raise the mower deck to its highest position to provide clearance for installing the blade.

3. Remove the Existing Blade:

– If there is a regular cutting blade already attached to the mower, it needs to be removed before installing the dethatching blade.

– Use a wrench or socket set to loosen and remove the nut or bolt that secures the existing blade to the mower’s spindle. Keep the nut or bolt in a safe place for reinstallation later.

4. Attach the Dethatching Blade:

– Align the center hole of the dethatching blade with the spindle on the mower deck.

– Slide the blade onto the spindle, ensuring that the blade’s cutting edges are facing downwards towards the ground.

– Insert the bolt or nut through the center hole of the blade and thread it onto the spindle. Use a wrench or socket set to tighten the bolt or nut securely.

– Follow the manufacturer’s instructions regarding the specific torque or tightening specifications for the blade attachment.

5. Reconnect Spark Plug Wire and Lower the Mower Deck:

– After the dethatching blade is securely attached, reconnect the spark plug wire to the spark plug.

– If you had raised the mower deck earlier, lower it to the desired cutting height for dethatching.

6. Safety Precautions:

– Before starting the lawn mower, ensure that there are no obstructions or objects near the mowing area that could interfere with the dethatching blade.

– Wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself during operation.

– Start the lawn mower’s engine and engage the blade according to the mower’s instructions, being cautious of the spinning dethatching blade.

It is important to note that the installation process may vary slightly depending on the specific lawn mower model and manufacturer. Always refer to the mower’s manual and follow the manufacturer’s instructions for safe and proper installation of the dethatching blade.

editor by CX 2023-12-04

China Densen customized CNC Machining High Quality Agriculture Machinery Parts, Hydraulic Press Machine Components Small Metal casting aftermarket agricultural parts

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

Agricultural Parts – The Best Metal for Agricultural Implements

Agricultural parts are used in almost every stage of cultivation and livestock management. The best metal for agricultural implements is steel. Agricultural equipment manufacturers are constantly trying to improve their products to better suit the needs of the farmer. In addition, they want to reduce the cost of repair. However, repairs on agricultural equipment are the responsibility of the farmer.

Steel is the best metal for agricultural implements

Choosing the right metal for agricultural implements can be tricky. There are different factors to consider, such as strength, elasticity, corrosion resistance, and ease of processing. All of these can seem to conflict with one another. However, steel has proven to be the best choice for agricultural equipment.

The metal is durable, affordable, and flexible. It can be customized to suit the characteristics of the agricultural equipment. It is also available in many grades, shapes, and thicknesses.

In addition, steel is environmentally friendly. It is resistant to chemicals and pesticides. It also maintains its integrity across a wide range of outdoor temperatures. It is also rust-resistant.

In addition to its strength, boron steel is also heat-resistant. It is also abrasion-resistant. Boron steel is used in agricultural machinery, chemical equipment, and other industrial units.

It is also highly corrosion-resistant. Agricultural processes are often exposed to harsh chemicals, dirt, and heat. Its low maintenance is also a good reason for farmers to use it.

The boron steel used for agricultural equipments also has the added benefit of an ultra-hard compound. It is used in the working parts of soil tillage machines. It is also used in food processing equipment.

The boron technology is a very effective way to prevent abrasive wear. It also increases the strength of the working parts of the agricultural equipments.

Modern farming is a very industrialized business. This is evident by the fact that most farm implements are made of low-alloy steel.

Technology has greatly shaped agriculture throughout time

Throughout history, technology has shaped agriculture, in both good and bad ways. It has been the catalyst of modernization and globalization. It has made travel and communication easier, increased business and education, and facilitated the building of cities.

There are several technological achievements that have made farming easier and more profitable. For example, genetic engineering is the way to go for many crops. Genetic modification makes crops more resistant to pests and weather, and preserves soil. Other advances include soilless farming methods and improved drip irrigation.

The most obvious benefit of modern agricultural technologies is the ability to produce more food with less labour. Precision farming also allows farmers to better care for their livestock. Many barns nowadays are equipped with Wi-Fi and automated feed systems. In addition, farmers can adjust the temperature in their barns using their smartphones.

There is no doubt that agriculture has undergone a paradigm shift in the last 50 years. In particular, the agricultural machinery and powered machinery have streamlined the mundane and transformed the way farmers operate. This is especially true for large scale farming.

Agricultural technology has improved the most mundane of farming tasks, such as weeding and watering. However, it has also led to new innovations in agriculture, such as genetically modified crops. Genetically modified crops are also known to conserve water and reduce carbon emissions.

The most important thing to remember about the aforementioned technological feats is that they have a cost. While it may be expensive to upgrade a whole farm, investing in a few technological breakthroughs can help farmers to achieve their goals and minimize problems along the way.

COVID-19 has been the biggest catalyst to supply chain breakdowns for farm equipment manufacturers

Among the most damaging effects of the COVID-19 pandemic has been the supply chain breakdowns in the farm equipment industry. According to a survey conducted by the Assn. of Equipment Manufacturers, 105 respondents weighed in on the effects of the pandemic on their business and industry.

The survey found that seven out of 10 executives have experienced a moderate impact on their supply chain. A quarter of respondents reported that the impact was extremely negative. AEM’s members are leading the industry’s response to the pandemic and are working with federal and state officials to mitigate its spread.

While the effects of the pandemic are still being felt worldwide, the U.S. economy is showing signs of recovery. However, there are still significant disruptions in the supply chain.

One reason why equipment manufacturers have been able to lead the country’s recovery is because of the efforts they’ve made to protect their employees. Most equipment requires hundreds of different components. Many manufacturers are stepping up to help keep employees safe by expediting raw materials and providing incentives to stay on the job.

However, even though the economy is improving, labor shortages are expected to persist. This is a problem that could amplify the imbalance among channels.

Some companies have been bringing back mothballed production lines to service and focusing on just-in-time delivery of raw materials and component parts. Some companies have also increased e-commerce sales and engaged new suppliers.

Intercropping prevents moisture loss and soil erosion

Agricultural practices such as intercropping are a key part of preventing moisture loss and soil erosion. It has been practiced for thousands of years, especially in temperate regions. However, the industrialization of agriculture in the 20th century led to the abandonment of intercropping in developed countries. The interest in organic farming has led First World farmers to return to intercropping.

In addition to reducing moisture loss and soil erosion, intercropping can also help to increase drought resistance. For example, intercropping maize with legumes can increase the soil moisture during peak rainfall. This improves soil hydrology and fertility, resulting in improved crop growth and yields.

The most effective crops to use for reducing soil erosion are legumes. Legumes have a dense root system and have a good canopy cover to protect the soil from the erosive effects of rainfall.

Soil erosion is a serious threat to agricultural sustainability. The amount of eroded soil directly deposited into reservoirs and beaches is approximately 29 percent of total soil erosion. In addition, more than half of eroded soil is transported by runoff. Agricultural practices that accelerate the erosion process must be reduced to avoid negative impacts on productivity.

In early experiments, researchers evaluated the effects of mixed cropping systems. They also investigated the interactions of different agricultural species. In a study on maize, Smith et al. found that legumes can meet protein needs in maize systems without increasing inputs.

Farmers use machines in almost every stage of cultivation and livestock management

Using machines in almost every stage of the agriculture cycle is no small feat. Most farmers still follow the old fashioned model of handpicking, shoveling, and baling. A modern day farmer could grow one thousand acres of corn. One may have a hard time keeping up with the herds on such a large scale. Some farmers have taken the lead in the modern era and are utilizing high tech solutions to their farming woes.

While many are still clinging to old school methods, modern day breeders and farmers have found the best way to produce high quality livestock is to modernize their facilities. Machines such as those pictured below are a boon to farmers and livestock alike. Machines such as these have also revolutionized the way farmers harvest crops. Machines such as these allow farmers to work the dirt with less abrasion and more precision. Many farmers are using machines to help with manure management, crop rotation, and weed control. Some have also tapped into the technology incorporated in these machines to enhance animal welfare. Some farmers are using technology such as these to make animal identification quicker and easier. Some farmers have even incorporated drones into their operations. Using drones in animal management has many benefits. Farmers are able to keep an eye on a small herd, reduce stress on a large herd, and improve the overall quality of the animals they produce.

editor by czh 2023-06-27

China OEM Small Order Custom Metal Machine Parts Manufacturing CNC Machining Service Metal Aluminum Brass Stainless Steel Agricultural Machines Parts agricultural trailer brake parts

Product Description

Small order Custom metal machine parts manufacturing CNC machining service metal aluminum brass stainless steel agricultural machines parts

Click here and specify your inquiry, contact us to get an online quote now!

About us

Full-service precision CNC machining services for prototypes and short and low to high production runs. Capabilities are CNC milled and turned metal parts and assemblies. Materials worked with include aluminum, brass, copper, stainless, steel, iron, other precious metals, and other plastic materials. Lead times are 2 to 3 weeks for prototypes and 4 to 6 weeks for production runs. Emergency and rush services are available. Industries served include aircraft and aerospace, consumer electronics, automotive, machinery fittings, audio equipment, EDC tools, computer, and Secondary processes such as anodizing, sandblasting, blackening, grinding, honing, heat treating, powder coating, passivation, polishing, plating, and brushing are also provided.

Examples projects

| Brass Machining Parts | ||

| Aluminum & Stainless Steel & Plastic Machining Parts | ||

Our Focus

|

Responsive We have invested significant time and effort in developing lasting relationships with both our customers, material/surface finish suppliers, and ZCM. Our ability to establish these partnerships enables ZCM to be extremely responsive. |

Quality Since the beginning, we pride ourselves on supplying high-end quality, competitively priced parts to some of the Chinese most prestigious companies. By using the latest inspection technology such as 2D CMM & 3DCMM and highly qualified staff we provide accurate parts at the tightest dimensions. |

Machining Services We excel in all areas of CNC milling and turning machining and Swiss machining. ZCM had machined thousands of parts for many different industries including aerospace, auto, consumer electronics, bike, and fittings, as well prototyping development products. |

Assembly Services One of our strengths lies in the ability to help the assembly for our customers their full turnkey products, from simple assembly to complicated assembly, which reduces much inconvenience for any extra work on the customers’ end. |

Hard-working team

Surface Finish

Comments from customers

Want to know more about us? Email us now!

| After-sales Service: | Email Us Anytime If Any Problems |

|---|---|

| Warranty: | Email Us Anytime If Any Requirements |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, Custom Metal Parts & Free Sample Offered, CE, RoHS, GS, ISO9001 |

| Customized: | Customized |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Agricultural Parts

Agricultural parts are a large part of the farming process. They are used for a number of purposes, including harvesting and transportation of crops. The parts are made from a variety of different materials, including metal, plastic and rubber. These materials have various advantages, including being resistant to pesticides and herbicides. In addition, they are easy to clean, allowing them to last for years.

Mechanization of farming

Agricultural mechanization, the use of mechanical technology to perform agricultural processes, has been an important tool in the modernization of agriculture. It increases farm worker productivity by replacing manual labor with powered machinery. It also provides employment opportunities for young people. Agricultural mechanization also has important environmental effects. It improves land usage and enhances agricultural productivity.

In Tanzania, agricultural mechanization has been slow but steady in the past few decades. In fact, the speed of mechanization growth varies across regions. In some parts of the country, the share of cultivated land plowed by tractors has reached around 50 percent.

The main drivers of agricultural mechanization in Tanzania are agroecological conditions and socioeconomic developments. This demand for mechanization depends on the capacity of farmers to fully use the machines and their complementary technologies.

The demand for mechanization has grown in parts of the country where there is a high demand for more intensive farming. In these regions, population growth has influenced the evolution of the farming system. This has led to a gradual transition from deep tillage to more intensive land preparation methods.

Mechanization has also been a catalyst for improved crop yields. Improved crop yields can be sold in markets and create indirect benefits for women. Women are commonly involved in weeding, transportation and postharvest management of agricultural produce.

The demand for mechanization has also been influenced by the growing share of the urban population. The urban population is expected to grow to 50 percent of the total population by 2030. The majority of rural-to-urban migrants are educated young people who are more likely to think of farming as a business.

In some parts of Tanzania, agricultural mechanization has been promoted by the public sector. This was in part a result of the government’s implementation of the Economic Structural Adjustment Program (ESAP). Public sector promotion of agricultural mechanization included the development of mechanization services, increased tractor supply, and the promotion of public-private partnerships.

CZPT Brand (r)

Agricultural machinery parts from CZPT Brand are renowned for their excellent quality. These parts are compatible with many agricultural engines including John Deere, Perkins & Massey Ferguson (r), Case IH, Ford, Detroit Diesel, and Komatsu (r) engines. These replacement engine parts ensure excellent durability and performance. They are also designed to meet the high standards of the original equipment manufacturer.

CZPT brand replacement agricultural parts are manufactured by a global company that is dedicated to consistently supporting its customers. The products are also designed to meet the needs of different types of agriculture. Their products are manufactured with the highest quality standards and they are backed by a 12-month warranty. This makes them the preferred parts supplier. They also have an extensive network of dealers across the globe.

CZPT Brand is a global company that specializes in providing high-quality engine parts for various agricultural machinery. It also specializes in providing replacement parts for tractor engines. It offers replacement gearboxes for a variety of engine types including John Deere, Detroit Diesel, and Cummins (r) engines. The parts are also compatible with lawn mowers and rotary cutters.

Agricultural machinery parts from CZPT Brand are known for their durability and excellent quality. They also offer lighting for optimum visibility and rear and side lights for maximum visibility. This ensures that the agricultural machinery performs at its best. These parts are also known for their excellent service. They are backed by a dedicated service team that is available to help you with any issues.

CZPT Brand agricultural parts are a perfect solution for John Deere, Perkins & Masey Ferguson, Case IH, Ford, Detroit Diesel, Komatsu (r) and IVECO Tector (r) engines.

CZPT Manufacturing

Founded in 1977, CZPT Manufacturing produces agricultural parts and accessories, primarily for use with farm equipment. The company began with a single page flyer at a farm trade show. In less than 50 years, the company has grown into a thriving, nationwide producer of agricultural replacement parts.

Currently, the company stocks parts for numerous manufacturers and offers a variety of products. These include personal protective equipment, knives, gathering chains, and forage harvester replacement parts. The company also offers apparel, including long-sleeved and youth shirts. The company also offers a fast and convenient shipping process.

editor by CX 2023-06-14

China factory Quality Small Gasoline Diesel Farm Garden Power Tiller Cultivator Rotary Tillage Machine Walking Tractor Disc Harrow Parts Outer Tyre near me manufacturer

Product Description

Quality Small Gasoline Diesel Farm Garden Power Tiller Cultivator Rotary Tillage Machine Walking Tractor Disc Harrow Parts Outer Tyre

Notes: What you see is ONLY a Small Part of our products Scope, you are pleased to let us know your exact parts requirement so that we can offer you the Right Parts with Right Cost, Just Right with US!

We Also Supply Other models of Tiller Parts , Feel Free to contact us for more information. Can Also Check CZPT Online to get our latest updates.

When your axle needs to be replaced

If you’re wondering when your axle needs to be replaced, you should be aware of these signs first. A damaged axle is usually a sign that your car is out of balance. To tell if the axle needs to be replaced, listen for the strange noise the wheels make as they move. A rhythmic popping sound when you hit bumps or turns indicates that your axle needs to be replaced. If this sounds familiar, you should visit a mechanic.

Symptoms of a broken shaft

You may notice a clicking or clanking sound from the rear of the vehicle. The vibrations you feel while driving may also indicate damaged axles. In severe cases, your car may lose control, resulting in a crash. If you experience these symptoms, it’s time to visit your auto repair shop. For just a few hundred dollars, you can get your car back on the road, and you don’t have to worry about driving.

Often, damaged axles can be caused by a variety of causes, including poor shock or load bearing bearings. Other causes of axle problems can be an overloaded vehicle, potholes, or a car accident. A bad axle can also cause vibrations and power transmission failures while driving. A damaged axle can also be the result of hitting a curb or pothole. When shaft damage is the cause of these symptoms, it must be repaired immediately.

If your car’s front axle is bent, you may need to replace them at the same time. In this case, you need to remove all tires from the car, separate the driveshaft from the transmission, and remove the axle. Be sure to double check the alignment to make sure everything is ok. Your insurance may cover the cost of repairs, but you may need to pay a deductible before getting coverage.

Axle damage is a common cause of vehicle instability. Axles are key components of a car that transmit power from the engine to the wheels. If it breaks, your vehicle will not be able to drive without a working axle. Symptoms of damaged axles can include high-speed vibrations or crashes that can shake the entire car. When it breaks down, your vehicle won’t be able to carry the weight of your vehicle, so it’s important to get your car repaired as soon as possible.

When your axle is damaged, the wheels will not turn properly, causing the vehicle to crash. When your car has these problems, the brakes won’t work properly and can make your car unstable. The wheels also won’t line up properly, which can cause the brakes to fail. Also, a damaged axle can cause the brakes to become sluggish and sensitive. In addition to the obvious signs, you can also experience the sound of metal rubbing against metal.

Types of car axles

When you’re shopping for a new or used car, it’s important to know that there are different types of axles. Knowing the year, make, model, trim and body type will help you determine the type you need. For easy purchasing, you can also visit My Auto Shop and fill out the vehicle information checklist. You can also read about drivetrains and braking systems. After mastering the basic information of the vehicle, you can purchase the axle assembly.

There are 2 basic types of automotive axles: short axles and drive axles. The axle is the suspension system of the vehicle. They carry the drive torque of the engine and distribute the weight throughout the vehicle. While short shafts have the advantage of simpler maintenance, dead shafts are more difficult to repair. They’re also less flexible, which means they need to be durable enough to withstand harsh conditions.

Axles can be 1 of 3 basic types, depending on the weight and required force. Semi-floating shafts have a bearing in the sleeve. They attach to the wheel and spin to generate torque. Semi-pontoons are common in light pickup trucks and medium-duty vehicles. They are not as effective as floating axles, but still provide a solid foundation for wheel alignment. To keep the wheels aligned, these axles are an important part of the car.

The front axle is the largest of the 3 and can handle road shocks. It consists of 4 main parts: stub shaft, beam, universal pin and track rod. The front axle is also very important as it helps with steering and handling road shocks. The front axle should be strong and durable, as the front axle is most susceptible to road shocks.

Cars use 2 types of axles: live and dead. Live axles connect to the wheels and drive the vehicle. Dead axles do not drive the wheels and support the vehicle. Those with 2 wheels have live axles. Heavy trucks and trailers use 3 or more. The number of axles varies according to the weight and load of the vehicle. This will affect which type of axle you need.

life expectancy

There are a few things to keep in mind when determining the life expectancy of an automotive axle. First, you should check for any signs of wear. A common sign is rust. If your vehicle is often driven in snow and ice, you may need to replace the axle. Also, you should listen for strange sounds from the wheels, such as rhythmic thumping.

Depending on the type of axle, your car may have an average lifespan of 70,000 miles. However, if you have an older car, the CV axles probably won’t last 5 years. In this case, you may wish to postpone the inspection. This way, you can save money on repairs. However, the next step is to replace the faulty CV shaft. This process can take anywhere from 1 hour to 3 hours.

Weaker axles will eventually break. If it were weakened, it would compromise the steering suspension, putting other road users at risk. Fortunately, proper maintenance will help extend the life of your axle. Here are some tips for extending its lifespan. A good rule of thumb is to never go over speed bumps. This will cause sudden breakage, possibly resulting in a car accident. To prolong the life of your vehicle’s axles, follow these tips.

Another thing to check is the CV connector. If loose, it can cause vibration or even breakage if not controlled. Loose axles can damage the body, suspension and differential. To make matters worse, the guard on the CV joint could tear prematurely, causing the shaft to come loose. Poor CV connections can damage the differential or transmission if left unchecked. So if you want to maximize the life expectancy of your car’s axles, consider getting them serviced as soon as possible.

The cost of repairing a damaged axle

A damaged axle may need repair as it is responsible for transferring power from the engine to the wheels. A damaged axle can cause a crash or even loss of control. Repairing an axle is much simpler than dealing with an accident. However, damaged axles can cost hundreds of dollars or more. Therefore, it is important to know what to do if you suspect that your axle may have a damaged component.

When your car needs to be replaced or repaired, you should seek the help of a professional mechanic to keep your car safe. You can save a lot of money by contacting a local mechanic who will provide the parts and labor needed to repair the axle. Also, you can avoid accidents by fixing your car as soon as possible. While axles can be expensive, they can last for many years.

The cost of repairing a damaged axle depends on the amount of repairs required and the vehicle you are driving. Prices range from $300 to $1,000, depending on the car and its age. In most cases, it will cost you less than $200 if you know how to fix a damaged axle. For those without DIY auto repair experience, a new axle can cost as little as $500. A damaged axle is a dangerous part of driving.

Fortunately, there are several affordable ways to repair damaged axles. Choosing a mechanic who specializes in this type of repair is critical. They will assess the damage and decide whether to replace or repair the part. In addition to this, they will also road test your car after completing the repairs. If you are unsure about repair procedures or costs, call a mechanic.

China Professional Quality Small Gasoline Diesel Farm Garden Power Tiller Cultivator Rotary Tillage Machine Walking Tractor Disc Harrow Spare Parts Fender Mudguard near me factory

Product Description

Quality Small Gasoline Diesel Farm Garden Power Tiller Cultivator Rotary Tillage Machine Walking Tractor Disc Harrow Spare Parts Fender Mudguard

Notes: What you see is ONLY a Small Part of our products Scope, you are pleased to let us know your exact parts requirement so that we can offer you the Right Parts with Right Cost, Just Right with US!

We Also Supply Other models of Tiller Parts , Feel Free to contact us for more information. Can Also Check CZPT Online to get our latest updates.

Mechanical advantages of pulleys

A pulley is a mechanical device used to transmit motion. The device has a variety of uses, including lifting heavy objects. In this article, we will discuss the mechanical advantages, types, common uses and safety considerations of pulleys. We’ll also discuss how to identify pulleys and their components, and what to look out for when using pulleys. Read on to learn more about pulleys.

Mechanical advantages of pulleys

The mechanical advantage of pulleys is that they change the direction of force from 1 direction to another. In this way, the person lifting the heavy object can change its position with minimal effort. The pulleys are also easy to install and require no lubrication after installation. They are also relatively cheap. Combinations of pulleys and cables can be used to change the direction of the load.

The mechanical advantage of a pulley system increases with the number of ropes used in the system. The more cycles a system has, the more efficient it is. If the system had only 1 rope, the force required to pull the weight would be equal. By adding a second rope, the effort required to pull the weight is reduced. This increase in efficiency is known as the mechanical advantage of the pulley.

Pulleys have many uses. For example, ziplines are 1 application. This is a good example of pulleys in use today. Pulley systems can be complex and require a lot of space. Using ziplines as an example, advanced students can calculate the mechanical advantage of multiple pulleys by dividing the work done by each pulley by the remainder or fraction. Regents at the University of Colorado created a zipline with K-12 input.

Another use for pulleys is weight lifting. This technique is very effective when using multiple strands of rope. A single rope going from 1 pulley to the other with just 2 hands is not enough to lift heavy objects. Using a pulley system will greatly increase the force you receive. This power is multiplied over a larger area. So your lifting force will be much greater than the force exerted by a single rope.

The pulley is a great invention with many uses. For example, when lifting heavy objects, pulleys are a great way to get the job done, and it’s easier to do than 1 person. The pulley is fixed on a hinge and rotates on a shaft or shaft. Then pull the rope down to lift the object. A pulley assembly will make the task easier. In addition, it will also allow power to be transferred from 1 rotary shaft to another.

Types of pulleys

If you are an engineer, you must have come across different types of pulleys. Some pulleys come in multiple types, but a typical pulley has only 1 type. These types of pulleys are used in various industrial processes. Here are some common types of pulleys that engineers encounter on the job. In addition to the above, there are many more. If you haven’t seen them in practice, you can check out a list of the different types below.

Fixed pulleys: Fixed pulleys have a roller attached to a fixed point. The force required to pull the load through the fixed pulley is the same as the force required to lift the object. Movable pulleys allow you to change the direction of the force, for example, by moving it laterally. Likewise, movable pulleys can be used to move heavy objects up and down. Commonly used in multi-purpose elevators, cranes and weight lifters.

Composite pulleys combine fixed and movable pulleys. This combination adds to the mechanical advantage of both systems. It can also change the direction of the force, making it easier to handle large loads. This article discusses the different types of pulleys used for lifting and moving. Braided pulleys are an example of these pulleys. They combine the advantages of both types.

A simple pulley consists of 1 or more wheels, which allow it to reverse the direction of the force used to lift the load. On the other hand, dual-wheel pulleys can help lift twice the weight. By combining multiple materials into 1 pulley, a higher ME will be required. Regardless of the type of pulley, understanding the principles behind it is critical.

Pulleys are an important part of construction and mechanical engineering, and their use dates back to Archimedes. They are a common feature of oil derricks and escalators. The main use of pulleys is to move heavy objects such as boats. In addition to this, they are used in other applications such as extending ladders and lifting heavy objects. The pulley also controls the aircraft rudder, which is important in many different applications.

Commonly used

Common uses for pulleys are varied. Pulley systems are found throughout most areas of the house, from adjustable clotheslines to motor pulleys in different machines. Commercially, 1 of the most common uses is for cranes. Cranes are equipped with pulleys to lift heavy objects. It is also common to use pulley systems in tall buildings, which allow tall buildings to move with relative ease.

Pulleys are commonly used in interception and zipline systems, where a continuous rope around the pulley transmits force. Depending on the application, the rope is either light or strong. Pulleys are formed by wrapping a rope around a set of wheels. The rope pulls the object in the direction of the applied force. Some elevators use this system. Pull a cable on 1 end and attach a counterweight on the other end.

Another common use for pulleys is to move heavy objects. Pulleys mounted on walls, ceilings or other objects can lift heavy objects like heavy toolboxes or 2×4 planks. The device can also be used to transfer power from 1 rotating shaft to another. When used to lift heavy objects, pulleys can be used to help you achieve your goals of a good workout.

Pulley systems have a variety of uses, from the most basic to the most advanced. Its popularity is indisputable and it is used in different industries. A good example is timing belts. These pulleys transmit power to other components in the same direction. They can also be static or dynamic depending on the needs of the machine. In most cases, the pulley system is custom made for the job.

Pulley systems can be simple or complex, but all 3 systems transfer energy efficiently. In most cases, the mechanical advantage of a single pulley is 1 and the mechanical advantage of a single active pulley is 2. On the other hand, a single live pulley only doubles the force. This means you can trade effort for distance. Pulleys are the perfect solution for many common applications.

Safety Notice

If you use pulleys, you need to take some safety precautions. First, make sure you’re wearing the correct protective gear. A hard hat is a must to avoid being hit by falling objects. You may also want to wear gloves for added protection. You should also maintain a good distance from the pulley so that nearby people can walk around it safely.

Another important safety measure to take before using a chain hoist is to barricade the area to be lifted. Use marker lines to prevent the load from sliding when moving horizontally. Finally, use only the sprocket set for vertical lift. Always install shackle pins before lifting. You should also wear personal protective equipment such as earplugs and safety glasses when using the chain hoist.

In addition to these safety measures, you should also use cables made from aerospace-grade nylon. They will last many cycles and are made of high quality materials. Also, make sure the cables are lubricated. These measures reduce friction and corrosion. No matter what industry you are in, be sure to follow these precautions to ensure a long service life for your cables. Consult the cable manufacturer if you are unsure of the appropriate material. A company with 60 years of experience in the cable industry can recommend the right material for your system.