Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

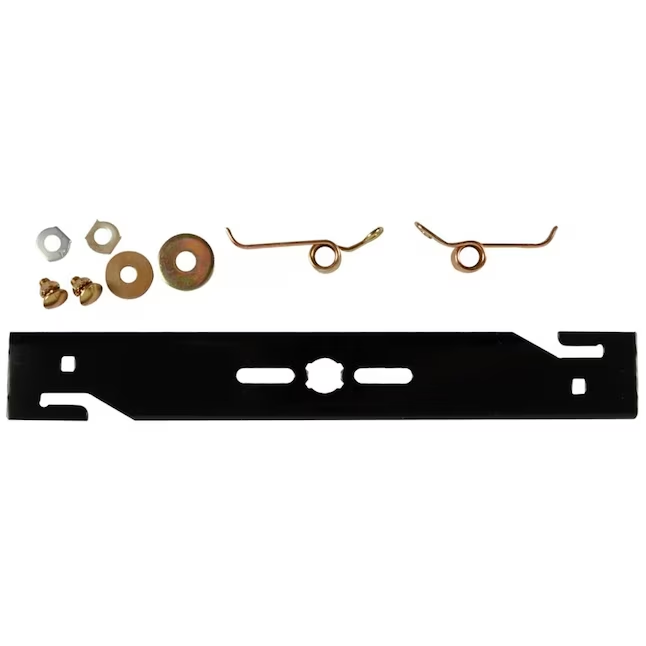

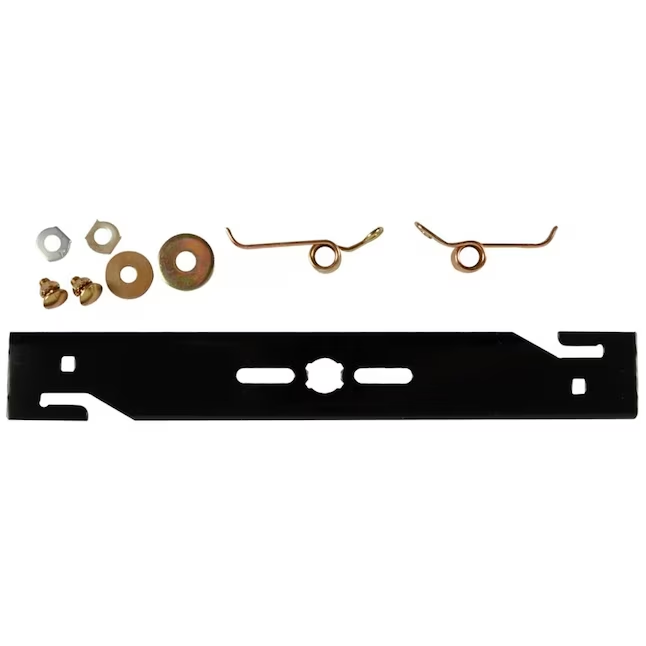

How does a dethatching blade work to remove thatch effectively?

A dethatching blade is a specialized tool designed to effectively remove thatch from lawns. Here’s a detailed explanation of how a dethatching blade works to remove thatch effectively:

A dethatching blade typically consists of multiple sharp, rigid tines or blades that are attached to a rotating shaft. When the blade is attached to a lawn mower or a dethatcher machine, the rotation of the blade allows the tines to penetrate the thatch layer and lift it from the surface of the soil.

1. Tine Penetration:

– As the dethatching blade rotates, the sharp tines or blades penetrate the thatch layer, which is the layer of dead grass, debris, and organic matter that accumulates between the grass blades and the soil surface.

– The tines are designed to reach deep enough to effectively lift the thatch without causing excessive damage to the healthy grass or the underlying soil.

2. Thatch Lifting:

– As the tines move through the thatch layer, they lift the accumulated debris and dead grass from the surface of the soil.

– The lifting action breaks up the thatch into smaller pieces, making it easier to remove and allowing better access to air, water, and nutrients for the underlying grass roots.

3. Thatch Removal:

– Once the thatch is lifted, it is either expelled from the machine or left on the surface of the lawn to be collected manually or through subsequent mowing and raking.

– Some dethatching blades may have additional features, such as a collection bag or a rear-mounted rake, to facilitate the removal of the lifted thatch.

4. Benefits of Dethatching:

– Dethatching with a dethatching blade offers several benefits for the health and appearance of the lawn:

– Improved Air Circulation: Removing the thatch layer allows better air circulation, reducing the risk of fungal diseases and promoting a healthier lawn.

– Enhanced Water Penetration: Thatch removal improves water penetration, preventing water runoff and ensuring that water reaches the grass roots more effectively.

– Increased Nutrient Absorption: Removing thatch allows nutrients to reach the grass roots, promoting healthier growth and greener grass.

– Improved Overall Lawn Health: By removing thatch, dethatching blades can help rejuvenate the lawn, resulting in a thicker, lusher, and more vibrant turf.

It’s important to note that the effectiveness of a dethatching blade depends on various factors such as the condition and thickness of the thatch layer, the type of grass, and the dethatching technique applied. It’s recommended to follow the manufacturer’s instructions and consider consulting with lawn care professionals for specific guidance on using a dethatching blade effectively.

What types of lawns require the use of a dethatching blade?

Not all lawns require the use of a dethatching blade, as the need for dethatching depends on the specific grass type and the extent of thatch buildup. Here’s a detailed explanation of the types of lawns that may require the use of a dethatching blade:

1. Lawns with Excessive Thatch:

– Lawns that have developed a thick layer of thatch, typically more than half an inch in depth, may require dethatching. Thatch buildup can occur due to factors such as infrequent mowing, over-fertilization, over-watering, or poor soil conditions.

– Thick thatch prevents air, water, and nutrients from reaching the grassroots, leading to poor lawn health, reduced vigor, and increased susceptibility to diseases and pests.

– Dethatching helps remove the excessive thatch layer, allowing the grass to breathe, absorb water and nutrients more effectively, and promote healthy growth.

2. Lawns with Cool-Season Grasses:

– Cool-season grasses, such as Kentucky bluegrass, perennial ryegrass, and tall fescue, are more prone to thatch buildup compared to warm-season grasses.

– These grasses tend to produce more above-ground stolons and rhizomes, which can contribute to the accumulation of thatch over time.

– Regular dethatching can be beneficial for lawns with cool-season grasses to maintain a healthy thatch level and prevent excessive buildup.

3. Lawns with Warm-Season Grasses:

– Warm-season grasses, such as Bermuda grass, Zoysia grass, and St. Augustine grass, generally have a lower tendency to develop thatch compared to cool-season grasses.

– However, in certain conditions, such as heavy fertilization or excessive irrigation, warm-season grasses can also accumulate thatch.

– While dethatching may not be a routine requirement for warm-season lawns, occasional dethatching can help maintain optimal lawn health, particularly if thatch buildup becomes problematic.

4. Lawns with Compacted Soil:

– Lawns with compacted soil can experience reduced water infiltration and poor air circulation, which can contribute to thatch accumulation.

– Compacted soil can impede the natural breakdown of organic matter, leading to an increased buildup of thatch.

– Dethatching, combined with aeration to alleviate soil compaction, can be beneficial for lawns with compacted soil, regardless of the grass type.

It is important to note that not all lawns require dethatching, and the decision to use a dethatching blade should be based on the specific conditions of the lawn. It is recommended to consult with a lawn care professional or a local cooperative extension office to determine if dethatching is necessary for your specific lawn type and condition.

editor by CX 2024-01-17

China supplier Factory Direct Sales Lawn Puncher Lawn Cultivator Weeding Machine Garden Cultivator Tool Aerator

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What are the safety precautions when using a dethatching blade?

When using a dethatching blade, it’s essential to prioritize safety to prevent accidents and injury. Here’s a detailed explanation of the safety precautions to follow when using a dethatching blade:

1. Read the Instructions:

– Carefully read and understand the manufacturer’s instructions and safety guidelines specific to your dethatching blade.

– Familiarize yourself with the recommended operating procedures, safety precautions, and any specific warnings or limitations.

2. Wear Protective Gear:

– Always wear appropriate personal protective equipment (PPE) when operating a dethatching blade.

– Safety goggles or glasses protect your eyes from debris, stones, and other flying objects.

– Safety gloves help protect your hands and fingers from sharp blades and potential injuries.

– Sturdy, non-slip footwear provides good traction and protects your feet from hazards.

– Consider wearing ear protection, such as earmuffs or earplugs, if the dethatching process generates excessive noise.

3. Inspect the Area:

– Before starting the dethatching process, inspect the area for any objects, such as rocks, branches, or toys, that could become projectiles when struck by the dethatching blade.

– Clear the lawn of any potential hazards to avoid damaging the blade or causing injury to yourself or others.

4. Secure Loose Clothing and Hair:

– Tie back long hair and avoid wearing loose clothing or accessories that could get caught in the dethatching blade.

– Loose items can be hazardous and may become entangled in the blade, leading to accidents or injuries.

5. Operate in Suitable Weather Conditions:

– Avoid operating the dethatching blade in wet or slippery conditions, as this can increase the risk of slips, falls, and loss of control.

– Rain or damp grass can also affect the dethatching process and the overall performance of the blade.

6. Use Caution on Slopes:

– Exercise caution when dethatching on slopes or uneven terrain.

– Maintain good footing and be aware of your balance to prevent slips, falls, or loss of control of the dethatching equipment.

– If the slope is too steep or challenging, it may be safer to seek professional assistance.

7. Switch off the Engine:

– Before performing any maintenance, adjustments, or blade inspections, ensure that the engine of your lawn mower or dethatcher is switched off and the spark plug is disconnected to prevent accidental starts.

8. Store the Blade Safely:

– When not in use, store the dethatching blade in a safe and secure location, out of reach of children and pets.

– Keep the blade away from moisture, sharp objects, and flammable materials to prevent accidents or damage.

Always prioritize safety when using a dethatching blade. Following these safety precautions will help minimize the risk of accidents, injuries, and equipment damage, allowing you to safely and effectively maintain your lawn.

What are the benefits of dethatching your lawn with a blade?

Dethatching your lawn with a blade can provide several benefits for the overall health and appearance of your grass. Here’s a detailed explanation of the benefits of dethatching:

1. Removal of Excessive Thatch:

– Thatch refers to the layer of dead grass, roots, and organic debris that accumulates between the soil and the healthy grass blades.

– Dethatching with a blade helps remove excessive thatch buildup, which can improve the lawn’s overall health and appearance.

2. Enhanced Nutrient and Water Absorption:

– Excessive thatch can act as a barrier, preventing water, air, and nutrients from reaching the grassroots and the soil.

– By dethatching, you create channels for better water penetration, improved air circulation, and enhanced nutrient absorption by the grass roots.

3. Promotion of New Growth:

– Dethatching stimulates new growth by allowing sunlight, water, and nutrients to reach the soil and grassroots more effectively.

– With the removal of thatch, the grass can develop healthier, stronger shoots and improved density, resulting in a more vibrant and lush lawn.

4. Reduction of Pest and Disease Risk:

– Excessive thatch provides an ideal environment for pests, such as insects and rodents, to thrive and hide.

– By dethatching, you eliminate potential habitats for pests, reducing the risk of infestations and minimizing the need for chemical treatments.

– Dethatching also helps prevent fungal diseases by improving air circulation and reducing moisture retention in the thatch layer.

5. Improved Lawn Aesthetics:

– Dethatching can significantly enhance the appearance of your lawn by removing the thick layer of dead material and creating a smoother, more uniform surface.

– A well-dethatched lawn has a healthier, greener, and more vibrant appearance, making it more visually appealing.

6. Enhanced Lawn Care Practices:

– Dethatching prepares the lawn for other essential lawn care practices, such as overseeding and aeration.

– After dethatching, overseeding can be performed to introduce new grass varieties and fill in bare patches, resulting in a denser and more resilient lawn.

– Additionally, aeration is more effective after dethatching, as it allows the soil to receive maximum benefits from the aeration process.

When dethatching your lawn, it is important to consider the specific grass type, the severity of thatch buildup, and the appropriate timing for the best results. Consulting with a lawn care professional or referring to the grass type’s specific guidelines can help ensure proper dethatching practices.

editor by CX 2024-01-17

China Custom Lawn Punching Machine Lawn Aerator Small Garden Tiller Small Cultivator

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How does a dethatching blade work to remove thatch effectively?

A dethatching blade is a specialized tool designed to effectively remove thatch from lawns. Here’s a detailed explanation of how a dethatching blade works to remove thatch effectively:

A dethatching blade typically consists of multiple sharp, rigid tines or blades that are attached to a rotating shaft. When the blade is attached to a lawn mower or a dethatcher machine, the rotation of the blade allows the tines to penetrate the thatch layer and lift it from the surface of the soil.

1. Tine Penetration:

– As the dethatching blade rotates, the sharp tines or blades penetrate the thatch layer, which is the layer of dead grass, debris, and organic matter that accumulates between the grass blades and the soil surface.

– The tines are designed to reach deep enough to effectively lift the thatch without causing excessive damage to the healthy grass or the underlying soil.

2. Thatch Lifting:

– As the tines move through the thatch layer, they lift the accumulated debris and dead grass from the surface of the soil.

– The lifting action breaks up the thatch into smaller pieces, making it easier to remove and allowing better access to air, water, and nutrients for the underlying grass roots.

3. Thatch Removal:

– Once the thatch is lifted, it is either expelled from the machine or left on the surface of the lawn to be collected manually or through subsequent mowing and raking.

– Some dethatching blades may have additional features, such as a collection bag or a rear-mounted rake, to facilitate the removal of the lifted thatch.

4. Benefits of Dethatching:

– Dethatching with a dethatching blade offers several benefits for the health and appearance of the lawn:

– Improved Air Circulation: Removing the thatch layer allows better air circulation, reducing the risk of fungal diseases and promoting a healthier lawn.

– Enhanced Water Penetration: Thatch removal improves water penetration, preventing water runoff and ensuring that water reaches the grass roots more effectively.

– Increased Nutrient Absorption: Removing thatch allows nutrients to reach the grass roots, promoting healthier growth and greener grass.

– Improved Overall Lawn Health: By removing thatch, dethatching blades can help rejuvenate the lawn, resulting in a thicker, lusher, and more vibrant turf.

It’s important to note that the effectiveness of a dethatching blade depends on various factors such as the condition and thickness of the thatch layer, the type of grass, and the dethatching technique applied. It’s recommended to follow the manufacturer’s instructions and consider consulting with lawn care professionals for specific guidance on using a dethatching blade effectively.

What is a dethatching blade and how is it used?

A dethatching blade is a gardening tool designed to remove thatch from lawns. Thatch is a layer of dead grass, roots, and other organic debris that accumulates between the soil and the healthy grass blades. Here’s a detailed explanation of what a dethatching blade is and how it is used:

1. Definition and Design:

– A dethatching blade is a specialized attachment or accessory that is typically used with a lawnmower or a power rake machine. It consists of a series of sharp, rigid blades or tines arranged in a row.

– The blades or tines of the dethatching blade penetrate the grass and soil, effectively cutting through the thatch layer and lifting it to the surface for removal.

2. Purpose and Benefits:

– The primary purpose of using a dethatching blade is to remove the thatch layer from the lawn. Excessive thatch can prevent air, water, and nutrients from reaching the grassroots, leading to poor lawn health and growth.

– By dethatching the lawn, the grass can better absorb water and nutrients, allowing for improved root development, enhanced overall health, and a more attractive appearance.

3. Usage and Technique:

– Before using a dethatching blade, it is important to ensure that the grass is dry to avoid damaging the turf. Wet grass can be more susceptible to tearing or uprooting.

– The dethatching blade attachment is typically installed on a lawnmower or a power rake machine, following the manufacturer’s instructions.

– When using the dethatching blade, the lawnmower or power rake is moved over the lawn in a systematic pattern, similar to regular mowing, but at a slightly slower pace.

– As the blades or tines rotate or move across the lawn, they cut through the thatch layer, pulling it up and depositing it on the surface in thin strips or clumps.

– After dethatching, the accumulated thatch can be raked or collected and disposed of. Some homeowners may choose to leave a thin layer of thatch behind, depending on the recommendations for their specific grass type.

4. Timing and Frequency:

– Dethatching is typically performed during the growing season when the grass is actively growing and can recover quickly from the process.

– The frequency of dethatching depends on the severity of thatch buildup and the type of grass. In general, it is recommended to dethatch every 1-3 years or as needed.

– Over-dethatching or performing the process too frequently can damage the grass and disrupt the turf’s natural balance.

5. Additional Lawn Care Practices:

– Dethatching is often combined with other lawn care practices, such as aeration and overseeding, to further improve the health and appearance of the lawn.

– Aeration helps alleviate soil compaction and improves the movement of air, water, and nutrients to the grassroots. Overseeding helps introduce new grass varieties and fills in bare patches.

In summary, a dethatching blade is a garden tool used to remove thatch from lawns. It is designed to cut through the thatch layer and lift it to the surface for removal, allowing for improved lawn health and growth.

editor by CX 2024-01-15

China Standard Lawn Punching Machine Lawn Aerator Small Garden Tiller Small Cultivator

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do you maintain and care for a dethatching blade?

Maintaining and caring for a dethatching blade is essential to ensure its optimal performance and longevity. Here’s a detailed explanation of how to maintain and care for a dethatching blade:

1. Clean the Blade:

– After each use, clean the dethatching blade to remove any grass clippings, debris, or thatch buildup.

– Use a brush or a hose to carefully scrub the blade and remove any stuck-on materials.

– Make sure the blade is completely dry before storing it to prevent rust or corrosion.

2. Inspect for Damage:

– Regularly inspect the dethatching blade for any signs of damage, such as bent or dull blades.

– If you notice any damage, replace the damaged parts or the entire blade if necessary.

– Using a damaged blade can result in poor dethatching performance and can potentially harm your lawn.

3. Sharpen the Blades:

– Over time, dethatching blades can become dull, which can affect their cutting efficiency.

– Sharpen the blades of the dethatching blade as needed using a sharpening stone or a file.

– Follow the manufacturer’s instructions or consult a professional if you’re unsure how to properly sharpen the blades.

4. Balance the Blade:

– A balanced dethatching blade is crucial for smooth operation and to prevent damage to your equipment.

– Check the balance of the dethatching blade by suspending it on a nail or a blade balancer.

– If the blade is unbalanced, it may cause excessive vibration or damage to the lawn mower or power rake machine.

– Adjust the balance by removing small amounts of material from the heavier side of the blade until it is properly balanced.

5. Store Properly:

– When the dethatching season is over or if you won’t be using the blade for an extended period, store it properly.

– Clean the blade thoroughly, ensure it is dry, and apply a thin coat of lubricating oil to prevent rust and corrosion.

– Store the dethatching blade in a dry and secure location, away from moisture and direct sunlight.

– Consider using a blade cover or sheath to protect the blade from accidental damage.

By following these maintenance and care practices, you can prolong the lifespan of your dethatching blade and ensure it remains in good working condition. Regular cleaning, inspection, sharpening, balancing, and proper storage will help maintain the blade’s performance, allowing for effective dethatching and a healthier lawn.

Are there any environmentally friendly dethatching blade options?

Yes, there are environmentally friendly dethatching blade options available that can help reduce the environmental impact of lawn care. Here’s a detailed explanation:

1. BioBlades:

– BioBlades are a type of dethatching blade that are designed with the environment in mind.

– These blades are typically made from biodegradable materials or recycled materials, reducing their impact on landfills.

– BioBlades are designed to break down naturally over time, minimizing waste and pollution.

2. Aerating Blades:

– Some dethatching blades come with aerating capabilities, which can be more environmentally friendly.

– Aerating blades have hollow tines or spikes that create small holes in the soil, improving air circulation, water penetration, and nutrient absorption.

– By incorporating aeration into the dethatching process, you can promote healthy soil and reduce the need for chemical fertilizers.

3. Electric-Powered Dethatching Tools:

– Electric-powered dethatching tools, such as electric dethatchers or electric lawn mowers with dethatching attachments, can be considered more environmentally friendly than their gas-powered counterparts.

– Electric tools produce zero emissions during operation, reducing air pollution and greenhouse gas emissions.

– Additionally, electric-powered tools are typically quieter, resulting in less noise pollution.

4. Sustainable Manufacturing:

– Consider dethatching blades from manufacturers that prioritize sustainable manufacturing practices.

– Look for brands that use eco-friendly materials, reduce waste generation, and implement energy-efficient production processes.

– Some manufacturers may also have recycling programs in place for their products, allowing you to dispose of old blades responsibly.

5. Organic Lawn Care Practices:

– In addition to using environmentally friendly dethatching blades, consider adopting organic lawn care practices.

– Regularly aerate and dethatch your lawn to promote healthy soil and reduce the need for chemical treatments.

– Use organic fertilizers, compost, and natural pest control methods to maintain a healthy and eco-friendly lawn.

– By adopting sustainable lawn care practices, you can minimize the environmental impact of your overall lawn care routine.

When looking for environmentally friendly dethatching blade options, consider factors such as the materials used, the manufacturing process, and the overall impact on the environment. Reading product descriptions, labels, and customer reviews can provide valuable insights into the eco-friendliness of different dethatching blades.

Remember that while using environmentally friendly dethatching blades is a step in the right direction, it’s also essential to consider the broader environmental impact of your lawn care practices and explore sustainable approaches to lawn maintenance.

How do you install a dethatching blade on a lawn mower?

Installing a dethatching blade on a lawn mower requires following specific steps to ensure proper attachment and safe operation. Here’s a detailed explanation of how to install a dethatching blade on a lawn mower:

1. Choose the Correct Blade:

– Ensure that you have the appropriate dethatching blade that is compatible with your specific lawn mower model. Refer to the manufacturer’s instructions or consult the mower’s manual to identify the correct blade type and size.

2. Prepare the Mower:

– Before installing the dethatching blade, turn off the lawn mower’s engine and disconnect the spark plug wire to prevent accidental starting.

– If necessary, raise the mower deck to its highest position to provide clearance for installing the blade.

3. Remove the Existing Blade:

– If there is a regular cutting blade already attached to the mower, it needs to be removed before installing the dethatching blade.

– Use a wrench or socket set to loosen and remove the nut or bolt that secures the existing blade to the mower’s spindle. Keep the nut or bolt in a safe place for reinstallation later.

4. Attach the Dethatching Blade:

– Align the center hole of the dethatching blade with the spindle on the mower deck.

– Slide the blade onto the spindle, ensuring that the blade’s cutting edges are facing downwards towards the ground.

– Insert the bolt or nut through the center hole of the blade and thread it onto the spindle. Use a wrench or socket set to tighten the bolt or nut securely.

– Follow the manufacturer’s instructions regarding the specific torque or tightening specifications for the blade attachment.

5. Reconnect Spark Plug Wire and Lower the Mower Deck:

– After the dethatching blade is securely attached, reconnect the spark plug wire to the spark plug.

– If you had raised the mower deck earlier, lower it to the desired cutting height for dethatching.

6. Safety Precautions:

– Before starting the lawn mower, ensure that there are no obstructions or objects near the mowing area that could interfere with the dethatching blade.

– Wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself during operation.

– Start the lawn mower’s engine and engage the blade according to the mower’s instructions, being cautious of the spinning dethatching blade.

It is important to note that the installation process may vary slightly depending on the specific lawn mower model and manufacturer. Always refer to the mower’s manual and follow the manufacturer’s instructions for safe and proper installation of the dethatching blade.

editor by CX 2023-12-04

China Densen customized CNC Machining High Quality Agriculture Machinery Parts, Hydraulic Press Machine Components Small Metal casting aftermarket agricultural parts

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

Agricultural Parts – The Best Metal for Agricultural Implements

Agricultural parts are used in almost every stage of cultivation and livestock management. The best metal for agricultural implements is steel. Agricultural equipment manufacturers are constantly trying to improve their products to better suit the needs of the farmer. In addition, they want to reduce the cost of repair. However, repairs on agricultural equipment are the responsibility of the farmer.

Steel is the best metal for agricultural implements

Choosing the right metal for agricultural implements can be tricky. There are different factors to consider, such as strength, elasticity, corrosion resistance, and ease of processing. All of these can seem to conflict with one another. However, steel has proven to be the best choice for agricultural equipment.

The metal is durable, affordable, and flexible. It can be customized to suit the characteristics of the agricultural equipment. It is also available in many grades, shapes, and thicknesses.

In addition, steel is environmentally friendly. It is resistant to chemicals and pesticides. It also maintains its integrity across a wide range of outdoor temperatures. It is also rust-resistant.

In addition to its strength, boron steel is also heat-resistant. It is also abrasion-resistant. Boron steel is used in agricultural machinery, chemical equipment, and other industrial units.

It is also highly corrosion-resistant. Agricultural processes are often exposed to harsh chemicals, dirt, and heat. Its low maintenance is also a good reason for farmers to use it.

The boron steel used for agricultural equipments also has the added benefit of an ultra-hard compound. It is used in the working parts of soil tillage machines. It is also used in food processing equipment.

The boron technology is a very effective way to prevent abrasive wear. It also increases the strength of the working parts of the agricultural equipments.

Modern farming is a very industrialized business. This is evident by the fact that most farm implements are made of low-alloy steel.

Technology has greatly shaped agriculture throughout time

Throughout history, technology has shaped agriculture, in both good and bad ways. It has been the catalyst of modernization and globalization. It has made travel and communication easier, increased business and education, and facilitated the building of cities.

There are several technological achievements that have made farming easier and more profitable. For example, genetic engineering is the way to go for many crops. Genetic modification makes crops more resistant to pests and weather, and preserves soil. Other advances include soilless farming methods and improved drip irrigation.

The most obvious benefit of modern agricultural technologies is the ability to produce more food with less labour. Precision farming also allows farmers to better care for their livestock. Many barns nowadays are equipped with Wi-Fi and automated feed systems. In addition, farmers can adjust the temperature in their barns using their smartphones.

There is no doubt that agriculture has undergone a paradigm shift in the last 50 years. In particular, the agricultural machinery and powered machinery have streamlined the mundane and transformed the way farmers operate. This is especially true for large scale farming.

Agricultural technology has improved the most mundane of farming tasks, such as weeding and watering. However, it has also led to new innovations in agriculture, such as genetically modified crops. Genetically modified crops are also known to conserve water and reduce carbon emissions.

The most important thing to remember about the aforementioned technological feats is that they have a cost. While it may be expensive to upgrade a whole farm, investing in a few technological breakthroughs can help farmers to achieve their goals and minimize problems along the way.

COVID-19 has been the biggest catalyst to supply chain breakdowns for farm equipment manufacturers

Among the most damaging effects of the COVID-19 pandemic has been the supply chain breakdowns in the farm equipment industry. According to a survey conducted by the Assn. of Equipment Manufacturers, 105 respondents weighed in on the effects of the pandemic on their business and industry.

The survey found that seven out of 10 executives have experienced a moderate impact on their supply chain. A quarter of respondents reported that the impact was extremely negative. AEM’s members are leading the industry’s response to the pandemic and are working with federal and state officials to mitigate its spread.

While the effects of the pandemic are still being felt worldwide, the U.S. economy is showing signs of recovery. However, there are still significant disruptions in the supply chain.

One reason why equipment manufacturers have been able to lead the country’s recovery is because of the efforts they’ve made to protect their employees. Most equipment requires hundreds of different components. Many manufacturers are stepping up to help keep employees safe by expediting raw materials and providing incentives to stay on the job.

However, even though the economy is improving, labor shortages are expected to persist. This is a problem that could amplify the imbalance among channels.

Some companies have been bringing back mothballed production lines to service and focusing on just-in-time delivery of raw materials and component parts. Some companies have also increased e-commerce sales and engaged new suppliers.

Intercropping prevents moisture loss and soil erosion

Agricultural practices such as intercropping are a key part of preventing moisture loss and soil erosion. It has been practiced for thousands of years, especially in temperate regions. However, the industrialization of agriculture in the 20th century led to the abandonment of intercropping in developed countries. The interest in organic farming has led First World farmers to return to intercropping.

In addition to reducing moisture loss and soil erosion, intercropping can also help to increase drought resistance. For example, intercropping maize with legumes can increase the soil moisture during peak rainfall. This improves soil hydrology and fertility, resulting in improved crop growth and yields.

The most effective crops to use for reducing soil erosion are legumes. Legumes have a dense root system and have a good canopy cover to protect the soil from the erosive effects of rainfall.

Soil erosion is a serious threat to agricultural sustainability. The amount of eroded soil directly deposited into reservoirs and beaches is approximately 29 percent of total soil erosion. In addition, more than half of eroded soil is transported by runoff. Agricultural practices that accelerate the erosion process must be reduced to avoid negative impacts on productivity.

In early experiments, researchers evaluated the effects of mixed cropping systems. They also investigated the interactions of different agricultural species. In a study on maize, Smith et al. found that legumes can meet protein needs in maize systems without increasing inputs.

Farmers use machines in almost every stage of cultivation and livestock management

Using machines in almost every stage of the agriculture cycle is no small feat. Most farmers still follow the old fashioned model of handpicking, shoveling, and baling. A modern day farmer could grow one thousand acres of corn. One may have a hard time keeping up with the herds on such a large scale. Some farmers have taken the lead in the modern era and are utilizing high tech solutions to their farming woes.

While many are still clinging to old school methods, modern day breeders and farmers have found the best way to produce high quality livestock is to modernize their facilities. Machines such as those pictured below are a boon to farmers and livestock alike. Machines such as these have also revolutionized the way farmers harvest crops. Machines such as these allow farmers to work the dirt with less abrasion and more precision. Many farmers are using machines to help with manure management, crop rotation, and weed control. Some have also tapped into the technology incorporated in these machines to enhance animal welfare. Some farmers are using technology such as these to make animal identification quicker and easier. Some farmers have even incorporated drones into their operations. Using drones in animal management has many benefits. Farmers are able to keep an eye on a small herd, reduce stress on a large herd, and improve the overall quality of the animals they produce.

editor by czh 2023-06-27

China OEM Small Order Custom Metal Machine Parts Manufacturing CNC Machining Service Metal Aluminum Brass Stainless Steel Agricultural Machines Parts agricultural trailer brake parts

Product Description

Small order Custom metal machine parts manufacturing CNC machining service metal aluminum brass stainless steel agricultural machines parts

Click here and specify your inquiry, contact us to get an online quote now!

About us

Full-service precision CNC machining services for prototypes and short and low to high production runs. Capabilities are CNC milled and turned metal parts and assemblies. Materials worked with include aluminum, brass, copper, stainless, steel, iron, other precious metals, and other plastic materials. Lead times are 2 to 3 weeks for prototypes and 4 to 6 weeks for production runs. Emergency and rush services are available. Industries served include aircraft and aerospace, consumer electronics, automotive, machinery fittings, audio equipment, EDC tools, computer, and Secondary processes such as anodizing, sandblasting, blackening, grinding, honing, heat treating, powder coating, passivation, polishing, plating, and brushing are also provided.

Examples projects

| Brass Machining Parts | ||

| Aluminum & Stainless Steel & Plastic Machining Parts | ||

Our Focus

|

Responsive We have invested significant time and effort in developing lasting relationships with both our customers, material/surface finish suppliers, and ZCM. Our ability to establish these partnerships enables ZCM to be extremely responsive. |

Quality Since the beginning, we pride ourselves on supplying high-end quality, competitively priced parts to some of the Chinese most prestigious companies. By using the latest inspection technology such as 2D CMM & 3DCMM and highly qualified staff we provide accurate parts at the tightest dimensions. |

Machining Services We excel in all areas of CNC milling and turning machining and Swiss machining. ZCM had machined thousands of parts for many different industries including aerospace, auto, consumer electronics, bike, and fittings, as well prototyping development products. |

Assembly Services One of our strengths lies in the ability to help the assembly for our customers their full turnkey products, from simple assembly to complicated assembly, which reduces much inconvenience for any extra work on the customers’ end. |

Hard-working team

Surface Finish

Comments from customers

Want to know more about us? Email us now!

| After-sales Service: | Email Us Anytime If Any Problems |

|---|---|

| Warranty: | Email Us Anytime If Any Requirements |

| Condition: | New |

| Certification: | CE, RoHS, GS, ISO9001 |

| Standard: | DIN, Custom Metal Parts & Free Sample Offered, CE, RoHS, GS, ISO9001 |

| Customized: | Customized |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Agricultural Parts

Agricultural parts are a large part of the farming process. They are used for a number of purposes, including harvesting and transportation of crops. The parts are made from a variety of different materials, including metal, plastic and rubber. These materials have various advantages, including being resistant to pesticides and herbicides. In addition, they are easy to clean, allowing them to last for years.

Mechanization of farming

Agricultural mechanization, the use of mechanical technology to perform agricultural processes, has been an important tool in the modernization of agriculture. It increases farm worker productivity by replacing manual labor with powered machinery. It also provides employment opportunities for young people. Agricultural mechanization also has important environmental effects. It improves land usage and enhances agricultural productivity.

In Tanzania, agricultural mechanization has been slow but steady in the past few decades. In fact, the speed of mechanization growth varies across regions. In some parts of the country, the share of cultivated land plowed by tractors has reached around 50 percent.

The main drivers of agricultural mechanization in Tanzania are agroecological conditions and socioeconomic developments. This demand for mechanization depends on the capacity of farmers to fully use the machines and their complementary technologies.

The demand for mechanization has grown in parts of the country where there is a high demand for more intensive farming. In these regions, population growth has influenced the evolution of the farming system. This has led to a gradual transition from deep tillage to more intensive land preparation methods.

Mechanization has also been a catalyst for improved crop yields. Improved crop yields can be sold in markets and create indirect benefits for women. Women are commonly involved in weeding, transportation and postharvest management of agricultural produce.

The demand for mechanization has also been influenced by the growing share of the urban population. The urban population is expected to grow to 50 percent of the total population by 2030. The majority of rural-to-urban migrants are educated young people who are more likely to think of farming as a business.

In some parts of Tanzania, agricultural mechanization has been promoted by the public sector. This was in part a result of the government’s implementation of the Economic Structural Adjustment Program (ESAP). Public sector promotion of agricultural mechanization included the development of mechanization services, increased tractor supply, and the promotion of public-private partnerships.

CZPT Brand (r)

Agricultural machinery parts from CZPT Brand are renowned for their excellent quality. These parts are compatible with many agricultural engines including John Deere, Perkins & Massey Ferguson (r), Case IH, Ford, Detroit Diesel, and Komatsu (r) engines. These replacement engine parts ensure excellent durability and performance. They are also designed to meet the high standards of the original equipment manufacturer.

CZPT brand replacement agricultural parts are manufactured by a global company that is dedicated to consistently supporting its customers. The products are also designed to meet the needs of different types of agriculture. Their products are manufactured with the highest quality standards and they are backed by a 12-month warranty. This makes them the preferred parts supplier. They also have an extensive network of dealers across the globe.

CZPT Brand is a global company that specializes in providing high-quality engine parts for various agricultural machinery. It also specializes in providing replacement parts for tractor engines. It offers replacement gearboxes for a variety of engine types including John Deere, Detroit Diesel, and Cummins (r) engines. The parts are also compatible with lawn mowers and rotary cutters.

Agricultural machinery parts from CZPT Brand are known for their durability and excellent quality. They also offer lighting for optimum visibility and rear and side lights for maximum visibility. This ensures that the agricultural machinery performs at its best. These parts are also known for their excellent service. They are backed by a dedicated service team that is available to help you with any issues.

CZPT Brand agricultural parts are a perfect solution for John Deere, Perkins & Masey Ferguson, Case IH, Ford, Detroit Diesel, Komatsu (r) and IVECO Tector (r) engines.

CZPT Manufacturing

Founded in 1977, CZPT Manufacturing produces agricultural parts and accessories, primarily for use with farm equipment. The company began with a single page flyer at a farm trade show. In less than 50 years, the company has grown into a thriving, nationwide producer of agricultural replacement parts.

Currently, the company stocks parts for numerous manufacturers and offers a variety of products. These include personal protective equipment, knives, gathering chains, and forage harvester replacement parts. The company also offers apparel, including long-sleeved and youth shirts. The company also offers a fast and convenient shipping process.

editor by CX 2023-06-14

China 3W-30 Backpack Mist Duster 2 Stroke Gasoline Knapsack Sprayer for Agricultural Machine Garden Tools With EPA Standard agricultural parts UK

Sprayer Sort: Knapsack

Utilization: Agriculture

Relevant Industries: Farms, Property Use

Showroom Place: None

Diameter: a hundred and twenty inch

Condition: New

Warranty: 1 Calendar year

Important Selling Factors: Lengthy Service Existence

Right after Warranty Provider: On the web support, Spare components

Nearby Service Location: None

After-sales Services Presented: On the internet help

Packaging Particulars: Common Carton Box

Port: ZheJiang ,HangZhou

3W-thirty Backpack Mist Duster 2 Stroke Gasoline Knapsack Sprayer With EPA Regular for Agricultural Device Garden Equipment

| Design: | 3W-30 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Motor: | 2 Stroke | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Displacement: | 63cc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||