Product Description

Product: Custom molded rubber spare parts for auto

Customized rubber parts are widely used in many areas in our daily life. Rubber products (rubber product) refers to the activities of producing a variety of rubber products with natural and synthetic rubber as raw materials, and also the rubber products produced by the use of waste rubber. The output of synthetic rubber has greatly exceeded that of natural rubber, and the largest yield is styrene butadiene rubber.

Customized rubber products are made from rubber raw materials made from refiners, and they are designed according to the properties of the rubber products required, and the required hardness of the products is determined. The molding process is moulded by rubber plate vulcanizing machine. Finally, the product is processed by flash processing to smooth the surface of the product without burrs.

Product Details:

Materials: Nitrile rubber(NBR), Viton rubber(FKM), Silicone rubber, EPDM, Natural ruber.

Other Names: Auto rubber parts, rubber seal strips, rubber sealing, oil seals, rubber shock absorber.

Hardness: Shore A 50 -85

Operating temperature: -30 – 200 °C

Color: Red, Green, Blue, White, Black,Grey

Application: Custom molded rubber spare parts are used for pressure cooker, home appliance, autos, trucks, air-conditioners and etc.

The different material of rubber mounting will cause different property.

EPDM/NBR/silicone/SBR/PP/PVC etc.

| Items | EPDM | NR | silicone | PVC |

| Hardness (Sha) |

30~85 | 30~90 | 20~85 | 50~95 |

| Tensile strength (Mpa) |

≥8.5MPa | > 20 Mpa | 3~8 | 10~50 |

| Elongation(%) | 200~550 | 1000% | 200~800 | 200~600 |

| Specific Gravity | 0.75-1.6 | 1.15-1.21 | 1.25~1.35 | 1.3~1.7 |

| Temperature range | -40~+120°C | -50~70ºC. | -55~+350°C | -29°C – 65.5°C |

1. the property of NR

It has good wear resistance, high elasticity, breaking strength and elongation, But in the air, it is easy to get age, and it is get sticky when it get in touch with heat, which is easy to expand and dissolve in mineral oil or gasoline, but it is resistant to strong acid, but not to Alkali . working temperature is -50~70ºC.

2. the property of EPDM

Weather ability, aging resistance, CZPT resistance, chemical stability are excellent, and CFCS and a variety of refrigerants. Working temperature is -50~150

3. the property of silicone

It has excellent heat resistance, cold resistance, CZPT resistance and atmospheric aging resistant.Good electrical insulation performance,The tensile strength and wear resistance are generally poor and has non- oil resistant. The working temperature is -55~250ºC

4. The property of NBR

Good oil resistance, heat resistance, abrasion resistance, solvent resistance and high – pressure oil,But it is not suitable for CZPT solvents, such as ketones, ozone, nitro-hydrocarbons, and chloroform. The working temperature is -40~120 ºC

5. the property of CR

It has good elasticity, wear resistance and atmospheric aging resistance. It is not afraid of violent distortion and flammability.Chemical stability. The working temperature is -40~100 ºC

6. The property of FKM

Excellent high temperature resistance,And have excellent chemical resistance, most oil and solvent (other than ketones and esters).cold resistance is not good.

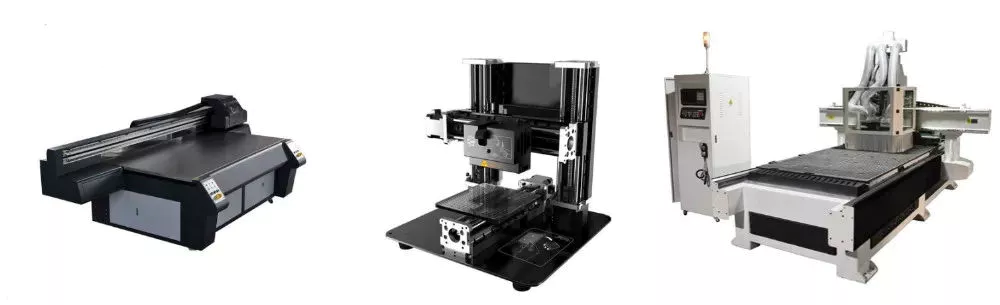

The advantage of our company

- We have complete production line with advanced production and test equipment..Adding First-class technicians, so that we can offer you the competitive price and high quality ,fast delivery time

- We have a special drawing design department to design the correct drawing data meeting your requirements. Then, we will use CAD or other format drawing to carry on tracking the production of tooling, sample ,mass goods. To avoid something wrong to each process. To make sure all of dimension are correct.

- We also has special production supervision department. The engineer staff will Supervise each process from the manufacture of tooling to the production of mass goods.

Reduce something wrong happened, finally offer you parts meeting your technology requirement. - All of Raw material are past quality certification,In the meantime, we will first delivery test report of rubber part when all of mass goods are finished. And make sure the quality meet your requirement, then make shipment.

-

Package and shipment

- Two part is packaged with 1 plastic bag, then certain quantity of rubber bellow seal are put into carton box.

- Carton box insider rubber bellow seal is with packing list detail. Such as, item name, the type number of rubber bellow seal, quantity of rubber bellow seal, gross weight,net weight, dimension of carton box,etc

- All of carton box will be put on 1 non-fumigation pallet, then all carton boxes will be wrapped by film.

4.We have our own forwarder which has Rich experience in delivery arrangement to optimize the most economic and quickest shipping way, SEA, AIR, DHL, UPS ,FEDEX, TNT , etc.

Why choose us?

1.Product: we specialize in rubber molding,injection and extruded rubber profile.

And complete advanced production equipment and test equipment

2.High quality:100% of the national standard has been no product quality complaints

the materials are environmentally friendly and the technology reaches the international advanced level

3.The competitive price:we have own factory, and the price is directly from factory. In additional,perfect advanced production equipment and enough staff. So the price is the best.

4.Quantity :Small quantity is available

5.Tooling:Developing tooling according to drawing or sample, and solve all of questions

6.Package: all of package meet standard internal export package, carton outside, inside plastic bag for each part; as your requirement

7.Transport:We have our own freight forwarder which can guarantee our goods can be delivered safely and promptly by sea or air

8.Stock and delivery:Standard specification,lots of stocks, and fast delivery

10. Service:Excellent service after-sales

Common Questions

- What is the minimum order quantity for your rubber products?

Answer:We didn’t set the minimum order quantity,1~10pcs some client has ordered.

- If we can get sample of rubber product from you?

Answer:Of course, you can. Feel free to contact me about it if you need it.

- Do we need to charge for customizing our own products? And if it is necessary to make tooling?

Answer: if we have the same or similar rubber part, at the same time, you satisfy it.

Well, you don’t need to open tooling

New rubber part, you will charge tooling according to the cost of tooling.

In additional,if the cost of tooling is more than 1000 USD, we will return all of them to you in the future when purchasing order quantity reach certain quantity our company rule

- How long you will get sample of rubber part?

Answer: Usually it is up to complexity degree of rubber part. Usually it take 7 to 10work

days.

- How many your company product rubber parts?

Answer:It is up to the size of tooling and the quantity of cavity of tooling. If rubber part is more complicate and much bigger, well maybe just make few, but if rubber part is small and simple, the quantity is more than 200,000pcs.

- Silicone part meet environment standard?

Answer:Our silicone part are all high grade 100% pure silicone material. We can offer you certification ROHS and SGS, FDA .Many of our products are exported to European and American countries. Such as: Straw, rubber diaphragm, food mechanical rubber, etc.

What You Need to Know About Ball Screws

A ball screw is a common industrial component used in various applications. Here’s a basic overview of their features, typical applications, and characteristics. You’ll also learn about their maintenance and repair options. Learn more about ball screws today. We’ve got the answers you’ve been looking for. Scroll down for more information. And be sure to check out our blog for future articles! Until then, enjoy browsing! And happy screwing!

Typical applications

Ball screws are threaded shafts with a ball nut attached to them. These screws operate similar to ball bearings in which hardened steel balls travel a channel. Ball screws are usually used in linear-motion applications because of their high efficiency, load capacity, and positioning accuracy. Although these screws are similar in design to conventional lead screws, ball screws offer some distinct advantages. For example, ball screws are often used in machine tools, step photolithography machines, and microscopic integrated circuits.

For example, the use of larger balls reduces backlash in ball screws by reducing friction between the balls and the grooves. Ball screws can be preloaded using a spring or spacer between 2 ball nuts or a lead with a spherical offset. However, this method requires higher torque and can lead to excessive heat generation. It’s important to consider the size of preload before using a ball screw in a particular application.

Although the ball screws are highly durable, they are not without their disadvantages. For example, their metal-on-metal nature makes them louder than lead screw nuts. For these reasons, proper preloading is vital. Ball screws also have a very low friction coefficient. Ball screws are ideal for applications where backlash is of critical importance, such as wire bonding. A ball screw is the perfect solution for many applications that require precise motion.

Although ball screws are used in a wide variety of applications, they often are exposed to various types of contaminants. Dust, chips, and liquids can interfere with proper lubrication and shorten the lifespan of the ball screw assembly. Ultimately, these contaminants can lead to catastrophic failure of the assembly. They are also prone to abrasive wear and tear. To combat this, it’s important to lubricate your ball screws frequently.

Characteristics

The accuracy of a ball screw is 1 of its primary characteristics, so choosing the correct grade is critical. A ball screw with a C5 accuracy grade is typically used in machining centers, while a C3 or even a C1 screw might be needed for image processing or inspection equipment. Ball screw hardness is also an important consideration, as differences in the Ct and C grades will affect their accuracy. Ultimately, the higher the quality of the ball, the longer its life expectancy.

Numerous studies have been conducted to understand the mechanics of ball screw mechanisms. Cuttino et al. studied the nonlinear torque characteristics of ball screws. Then, by calculating the distribution of loads in all balls, they analyzed the load on the screw shaft and the ball screw.

CZPT has decades of experience in the design and production of ball screws for industrial use. With close to 50 years of know-how, this company is able to respond to a highly-complex market and develop new solutions. Their ball screw ranges range from basic to high-precision. Moreover, they can provide dedicated solutions for specific applications, ensuring the highest quality under all circumstances. And they can meet specific customer needs and requirements thanks to their extensive research and development.

A ball screw must be properly mounted. Improper mounting results in noise and vibration, accelerated wear, and material failure. Also, installed auxiliary components must be checked for faults. And, since ball screw mechanisms are often multi-stage, there are different types of ball screw mechanisms. There are 2 basic types: internal and external recirculation systems. There are many differences between the 2 types, but these 2 types have some fundamental similarities.

Maintenance

Ball screw maintenance can be done easily if you know the symptoms of a deteriorating ball screw. Several signs of deterioration can be detected during regular inspections: excessive vibrations, discoloration, and misalignment of the screw. If the screw is accompanied by excessive noises, there could be a bent screw shaft or misaligned bearing housings. Excessive buildup can also cause clicking noises. If you notice excessive noises from the screw, the return tube has probably been damaged or is broken. Other common symptoms include loss of positioning accuracy due to endplay in support bearings and excessive power consumption.

Another sign of a malfunctioning ball screw is noise, but if you can identify the problem before it occurs, you can flush it. A proper flush can solve any noise or extend the life of the ball screw assembly. Moreover, flushing the assembly can also reveal if the bearings are damaged or galled. If the bearings are broken, you can replace them with new ones. You can also contact a professional to perform PM for ball screw assembly.

A ball screw manufacturer recommends periodic lubrication to maximize uptime. In fact, ball screws are pre-lubricated at the factory, but periodic attention to lubrication is advisable. In addition, the lubrication reservoir must be designed to minimize the loss of lubricant. Finally, the wiper system must be designed to maximize wear protection. It is important to have a wiper system that is capable of sealing the nut and the screw shaft.

To choose a company for your ball screw maintenance, it is important to check their qualifications. The company must have a long-term track record in the servicing of different types of ball screws. Their customer service should include free evaluation. Additionally, the company should offer 3 services: reload, recondition, and replacement. Reload requires cleaning and polishing, reconditioning requires regrinding the ball nut, and replacement means replacing the screw with a new one. If you need a ball screw repair, it is best to contact a professional.

Repair options

A damaged ball screw can shut down a manufacturing line unless the component is repaired quickly. Fortunately, there are several options for repair, including rebuilding, reconditioning, and replacement. Reconditioning and replacement involve remanufacturing the ball screw and ball nut, but both options require new parts. Choosing the best option for your ball screw will depend on how much damage it has suffered and the amount of money it will cost.

In most cases, ball screw repairs can be done on rolled and ground screw types. The process involves eutectic spraying and grinding the screw back to size. Among the 3 repair options, level 4 repair is the most expensive, but it can bring back the lifespan of the screw. Depending on the severity of damage, AB Linear may recommend level 3 repair to repair damaged ball screws. The following process will restore the screw to good working condition.

First, inspect the ball screw for signs of damage. If the ball screw is making unusual noises or vibrations, replace any worn seals or wipers. Discoloration of the ball nut or lead can indicate an inadequate lubrication. Damaged lube lines can also be the cause of a ball screw failure. Repairing these issues is often a cheaper option than purchasing new. By choosing to repair the component instead of replacing it, you will be saving up to 70% of the cost of a replacement ball screw.

If you do experience problems with your ball screw, the best option is to repair it. The cost of replacing a ball screw is prohibitively high, and it can be difficult to find a qualified repair company that specializes in repairing ball screws. A qualified company can repair the ball screw for a small fee. Regardless of the type of screw, it’s always a good idea to seek qualified assistance if it is experiencing any of these problems.

Application in steering systems

The conventional ball screw device is lacking a device to minimize noise and vibration. Both of these factors contribute to reduced performance and durability of a vehicle. The present invention overcomes these shortcomings. A ball screw device with a lower noise and vibration coefficient increases the durability and performance of a vehicle. In addition, it is easier to install and remove than the conventional version. Listed below are some advantages of ball screws in steering systems.

A ball screw is an important component of an automobile’s power steering system. This type of steering system requires a relatively low level of positional repeatability and precision. The screw is rotated by steering wheel motion and a ball nut engages with a Pitman arm. This arm is the primary linkage between the power steering box and the center link. By virtue of its low-cost and high-performance capabilities, ball screws are a desirable choice in many different automotive steering systems.

A ball screw device can be used in any electric power steering system. The shaft of the ball screw is threaded, and a ball nut is installed at its end. The screw includes a damper to reduce noise and vibration. The ball screw is often coupled with a power steering pump and electric motor to control the torque. In the present invention, the ball screw device incorporates a damper. This damper can increase the durability of the ball screw device.

As a leader in the manufacturing of ball screws, CZPT has been in the aerospace industry for decades. Its extensive experience and specialized expertise allows it to meet the diverse needs of the steering system market. Using this technology, CZPT offers a variety of solutions for this complex application. They can provide better positioning accuracy, higher durability and better control. So, if you’re in need of a ball screw in your steering system, contact CZPT today!