Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

What is the cost range for a quality dethatching blade?

The cost of a quality dethatching blade can vary depending on several factors, including the brand, the material used, the size, and the features of the blade. Here’s a detailed explanation of the cost range for a quality dethatching blade:

1. Basic Dethatching Blades:

– Basic dethatching blades without any special features or advanced materials are generally more affordable.

– The cost range for these blades can start as low as $10 and go up to around $30.

– These blades are suitable for occasional or light dethatching needs and may be a cost-effective option for small lawns or infrequent use.

2. Mid-Range Dethatching Blades:

– Mid-range dethatching blades offer better durability, performance, and materials compared to basic blades.

– The cost range for mid-range blades typically falls between $30 and $60.

– These blades may have additional features like enhanced tine design, improved aerating capabilities, or increased resistance to wear and tear.

– Mid-range blades are suitable for moderate dethatching needs and can be a good choice for most homeowners with average-sized lawns.

3. High-End Dethatching Blades:

– High-end dethatching blades are often constructed with premium materials and advanced design features.

– These blades offer superior durability, performance, and longevity, making them suitable for heavy-duty or professional use.

– The cost range for high-end dethatching blades can start around $60 and go up to $100 or more.

– These blades may have specialized tine configurations, improved aerating capabilities, or features that provide enhanced dethatching results.

– High-end blades are typically recommended for larger lawns, frequent use, or professional landscaping applications.

It’s important to note that the cost range provided above is a general estimate and may vary based on factors such as the specific brand, region, and availability. Additionally, prices may change over time due to market fluctuations and product updates.

When choosing a dethatching blade, it’s essential to consider your specific lawn care needs, budget, and the quality and durability you require. Reading product reviews, comparing prices from different retailers, and considering the reputation of the brand can help you make an informed decision and find a quality dethatching blade within your desired price range.

What are the benefits of dethatching your lawn with a blade?

Dethatching your lawn with a blade can provide several benefits for the overall health and appearance of your grass. Here’s a detailed explanation of the benefits of dethatching:

1. Removal of Excessive Thatch:

– Thatch refers to the layer of dead grass, roots, and organic debris that accumulates between the soil and the healthy grass blades.

– Dethatching with a blade helps remove excessive thatch buildup, which can improve the lawn’s overall health and appearance.

2. Enhanced Nutrient and Water Absorption:

– Excessive thatch can act as a barrier, preventing water, air, and nutrients from reaching the grassroots and the soil.

– By dethatching, you create channels for better water penetration, improved air circulation, and enhanced nutrient absorption by the grass roots.

3. Promotion of New Growth:

– Dethatching stimulates new growth by allowing sunlight, water, and nutrients to reach the soil and grassroots more effectively.

– With the removal of thatch, the grass can develop healthier, stronger shoots and improved density, resulting in a more vibrant and lush lawn.

4. Reduction of Pest and Disease Risk:

– Excessive thatch provides an ideal environment for pests, such as insects and rodents, to thrive and hide.

– By dethatching, you eliminate potential habitats for pests, reducing the risk of infestations and minimizing the need for chemical treatments.

– Dethatching also helps prevent fungal diseases by improving air circulation and reducing moisture retention in the thatch layer.

5. Improved Lawn Aesthetics:

– Dethatching can significantly enhance the appearance of your lawn by removing the thick layer of dead material and creating a smoother, more uniform surface.

– A well-dethatched lawn has a healthier, greener, and more vibrant appearance, making it more visually appealing.

6. Enhanced Lawn Care Practices:

– Dethatching prepares the lawn for other essential lawn care practices, such as overseeding and aeration.

– After dethatching, overseeding can be performed to introduce new grass varieties and fill in bare patches, resulting in a denser and more resilient lawn.

– Additionally, aeration is more effective after dethatching, as it allows the soil to receive maximum benefits from the aeration process.

When dethatching your lawn, it is important to consider the specific grass type, the severity of thatch buildup, and the appropriate timing for the best results. Consulting with a lawn care professional or referring to the grass type’s specific guidelines can help ensure proper dethatching practices.

editor by CX 2024-01-05

China Hot selling Lawn Punchermicro Tillerelectric Cultivatorlawn Aeratorefficiency High Quality and Good Operation Quasi-Welcome to Consult

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

|

|

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can dethatching blades be sharpened, and if so, how?

Yes, dethatching blades can be sharpened to restore their cutting efficiency. Here’s a detailed explanation of how to sharpen dethatching blades:

1. Gather the Necessary Tools:

– Before sharpening the dethatching blade, gather the necessary tools, including safety gloves, safety goggles, a vise or clamp, a file or sharpening stone, and a sturdy work surface.

2. Secure the Blade:

– Secure the dethatching blade in a vise or clamp to hold it steady during the sharpening process.

– Make sure the blade is firmly secured and positioned in a way that allows you to access the cutting edges easily.

3. Inspect the Blade:

– Before sharpening, carefully inspect the dethatching blade for any damage or excessive wear.

– If the blade is severely damaged, bent, or has worn-down tines, it may be more appropriate to replace the blade instead of sharpening it.

4. Sharpen the Cutting Edges:

– Use a file or sharpening stone to sharpen the cutting edges of the dethatching blade.

– Hold the file or sharpening stone at a consistent angle, typically matching the original angle of the cutting edge.

– Gently stroke the file or sharpening stone along the cutting edge in one direction, applying light pressure.

– Repeat the stroking motion several times, focusing on each cutting edge and maintaining a consistent angle.

– Remove any burrs or rough edges that may have formed during the sharpening process.

5. Balance the Blade:

– After sharpening, it’s essential to balance the dethatching blade to ensure smooth operation and prevent vibration.

– Check the balance of the blade by suspending it on a nail or a blade balancer.

– If one side of the blade is heavier, gently remove small amounts of material from the heavier side until the blade is properly balanced.

6. Clean and Test:

– Once the dethatching blade is sharpened and balanced, clean off any metal filings or debris.

– Reattach the blade to the dethatcher or mower and test its performance to ensure that it cuts effectively.

– If the blade still does not perform optimally, it may require further sharpening or replacement.

It’s important to note that the specific sharpening method may vary depending on the type of dethatching blade and the manufacturer’s recommendations. Always refer to the manufacturer’s instructions or consult a professional if you’re unsure about the sharpening process for your specific dethatching blade.

By following these steps and using proper safety precautions, you can sharpen your dethatching blade to restore its cutting ability and maintain effective dethatching performance.

What is the cost range for a quality dethatching blade?

The cost of a quality dethatching blade can vary depending on several factors, including the brand, the material used, the size, and the features of the blade. Here’s a detailed explanation of the cost range for a quality dethatching blade:

1. Basic Dethatching Blades:

– Basic dethatching blades without any special features or advanced materials are generally more affordable.

– The cost range for these blades can start as low as $10 and go up to around $30.

– These blades are suitable for occasional or light dethatching needs and may be a cost-effective option for small lawns or infrequent use.

2. Mid-Range Dethatching Blades:

– Mid-range dethatching blades offer better durability, performance, and materials compared to basic blades.

– The cost range for mid-range blades typically falls between $30 and $60.

– These blades may have additional features like enhanced tine design, improved aerating capabilities, or increased resistance to wear and tear.

– Mid-range blades are suitable for moderate dethatching needs and can be a good choice for most homeowners with average-sized lawns.

3. High-End Dethatching Blades:

– High-end dethatching blades are often constructed with premium materials and advanced design features.

– These blades offer superior durability, performance, and longevity, making them suitable for heavy-duty or professional use.

– The cost range for high-end dethatching blades can start around $60 and go up to $100 or more.

– These blades may have specialized tine configurations, improved aerating capabilities, or features that provide enhanced dethatching results.

– High-end blades are typically recommended for larger lawns, frequent use, or professional landscaping applications.

It’s important to note that the cost range provided above is a general estimate and may vary based on factors such as the specific brand, region, and availability. Additionally, prices may change over time due to market fluctuations and product updates.

When choosing a dethatching blade, it’s essential to consider your specific lawn care needs, budget, and the quality and durability you require. Reading product reviews, comparing prices from different retailers, and considering the reputation of the brand can help you make an informed decision and find a quality dethatching blade within your desired price range.

What are the benefits of dethatching your lawn with a blade?

Dethatching your lawn with a blade can provide several benefits for the overall health and appearance of your grass. Here’s a detailed explanation of the benefits of dethatching:

1. Removal of Excessive Thatch:

– Thatch refers to the layer of dead grass, roots, and organic debris that accumulates between the soil and the healthy grass blades.

– Dethatching with a blade helps remove excessive thatch buildup, which can improve the lawn’s overall health and appearance.

2. Enhanced Nutrient and Water Absorption:

– Excessive thatch can act as a barrier, preventing water, air, and nutrients from reaching the grassroots and the soil.

– By dethatching, you create channels for better water penetration, improved air circulation, and enhanced nutrient absorption by the grass roots.

3. Promotion of New Growth:

– Dethatching stimulates new growth by allowing sunlight, water, and nutrients to reach the soil and grassroots more effectively.

– With the removal of thatch, the grass can develop healthier, stronger shoots and improved density, resulting in a more vibrant and lush lawn.

4. Reduction of Pest and Disease Risk:

– Excessive thatch provides an ideal environment for pests, such as insects and rodents, to thrive and hide.

– By dethatching, you eliminate potential habitats for pests, reducing the risk of infestations and minimizing the need for chemical treatments.

– Dethatching also helps prevent fungal diseases by improving air circulation and reducing moisture retention in the thatch layer.

5. Improved Lawn Aesthetics:

– Dethatching can significantly enhance the appearance of your lawn by removing the thick layer of dead material and creating a smoother, more uniform surface.

– A well-dethatched lawn has a healthier, greener, and more vibrant appearance, making it more visually appealing.

6. Enhanced Lawn Care Practices:

– Dethatching prepares the lawn for other essential lawn care practices, such as overseeding and aeration.

– After dethatching, overseeding can be performed to introduce new grass varieties and fill in bare patches, resulting in a denser and more resilient lawn.

– Additionally, aeration is more effective after dethatching, as it allows the soil to receive maximum benefits from the aeration process.

When dethatching your lawn, it is important to consider the specific grass type, the severity of thatch buildup, and the appropriate timing for the best results. Consulting with a lawn care professional or referring to the grass type’s specific guidelines can help ensure proper dethatching practices.

editor by CX 2023-12-04

China Standard Lawn Punching Machine Lawn Aerator Small Garden Tiller Small Cultivator

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do you maintain and care for a dethatching blade?

Maintaining and caring for a dethatching blade is essential to ensure its optimal performance and longevity. Here’s a detailed explanation of how to maintain and care for a dethatching blade:

1. Clean the Blade:

– After each use, clean the dethatching blade to remove any grass clippings, debris, or thatch buildup.

– Use a brush or a hose to carefully scrub the blade and remove any stuck-on materials.

– Make sure the blade is completely dry before storing it to prevent rust or corrosion.

2. Inspect for Damage:

– Regularly inspect the dethatching blade for any signs of damage, such as bent or dull blades.

– If you notice any damage, replace the damaged parts or the entire blade if necessary.

– Using a damaged blade can result in poor dethatching performance and can potentially harm your lawn.

3. Sharpen the Blades:

– Over time, dethatching blades can become dull, which can affect their cutting efficiency.

– Sharpen the blades of the dethatching blade as needed using a sharpening stone or a file.

– Follow the manufacturer’s instructions or consult a professional if you’re unsure how to properly sharpen the blades.

4. Balance the Blade:

– A balanced dethatching blade is crucial for smooth operation and to prevent damage to your equipment.

– Check the balance of the dethatching blade by suspending it on a nail or a blade balancer.

– If the blade is unbalanced, it may cause excessive vibration or damage to the lawn mower or power rake machine.

– Adjust the balance by removing small amounts of material from the heavier side of the blade until it is properly balanced.

5. Store Properly:

– When the dethatching season is over or if you won’t be using the blade for an extended period, store it properly.

– Clean the blade thoroughly, ensure it is dry, and apply a thin coat of lubricating oil to prevent rust and corrosion.

– Store the dethatching blade in a dry and secure location, away from moisture and direct sunlight.

– Consider using a blade cover or sheath to protect the blade from accidental damage.

By following these maintenance and care practices, you can prolong the lifespan of your dethatching blade and ensure it remains in good working condition. Regular cleaning, inspection, sharpening, balancing, and proper storage will help maintain the blade’s performance, allowing for effective dethatching and a healthier lawn.

Are there any environmentally friendly dethatching blade options?

Yes, there are environmentally friendly dethatching blade options available that can help reduce the environmental impact of lawn care. Here’s a detailed explanation:

1. BioBlades:

– BioBlades are a type of dethatching blade that are designed with the environment in mind.

– These blades are typically made from biodegradable materials or recycled materials, reducing their impact on landfills.

– BioBlades are designed to break down naturally over time, minimizing waste and pollution.

2. Aerating Blades:

– Some dethatching blades come with aerating capabilities, which can be more environmentally friendly.

– Aerating blades have hollow tines or spikes that create small holes in the soil, improving air circulation, water penetration, and nutrient absorption.

– By incorporating aeration into the dethatching process, you can promote healthy soil and reduce the need for chemical fertilizers.

3. Electric-Powered Dethatching Tools:

– Electric-powered dethatching tools, such as electric dethatchers or electric lawn mowers with dethatching attachments, can be considered more environmentally friendly than their gas-powered counterparts.

– Electric tools produce zero emissions during operation, reducing air pollution and greenhouse gas emissions.

– Additionally, electric-powered tools are typically quieter, resulting in less noise pollution.

4. Sustainable Manufacturing:

– Consider dethatching blades from manufacturers that prioritize sustainable manufacturing practices.

– Look for brands that use eco-friendly materials, reduce waste generation, and implement energy-efficient production processes.

– Some manufacturers may also have recycling programs in place for their products, allowing you to dispose of old blades responsibly.

5. Organic Lawn Care Practices:

– In addition to using environmentally friendly dethatching blades, consider adopting organic lawn care practices.

– Regularly aerate and dethatch your lawn to promote healthy soil and reduce the need for chemical treatments.

– Use organic fertilizers, compost, and natural pest control methods to maintain a healthy and eco-friendly lawn.

– By adopting sustainable lawn care practices, you can minimize the environmental impact of your overall lawn care routine.

When looking for environmentally friendly dethatching blade options, consider factors such as the materials used, the manufacturing process, and the overall impact on the environment. Reading product descriptions, labels, and customer reviews can provide valuable insights into the eco-friendliness of different dethatching blades.

Remember that while using environmentally friendly dethatching blades is a step in the right direction, it’s also essential to consider the broader environmental impact of your lawn care practices and explore sustainable approaches to lawn maintenance.

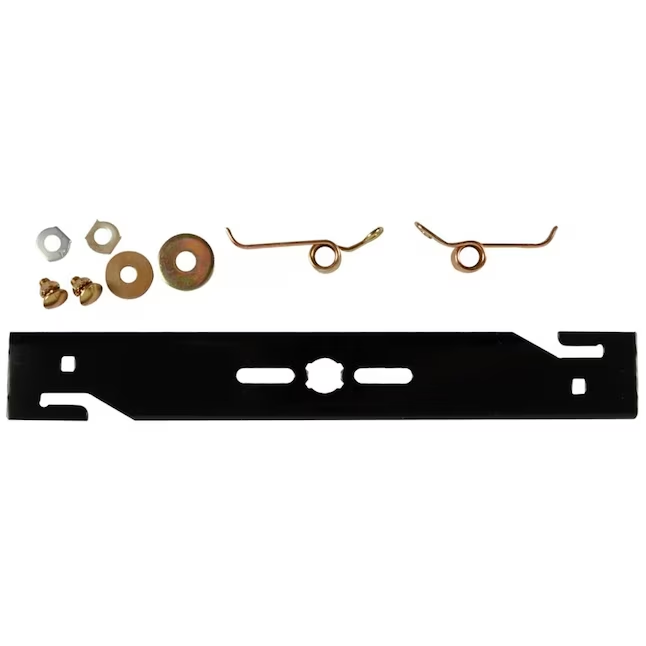

How do you install a dethatching blade on a lawn mower?

Installing a dethatching blade on a lawn mower requires following specific steps to ensure proper attachment and safe operation. Here’s a detailed explanation of how to install a dethatching blade on a lawn mower:

1. Choose the Correct Blade:

– Ensure that you have the appropriate dethatching blade that is compatible with your specific lawn mower model. Refer to the manufacturer’s instructions or consult the mower’s manual to identify the correct blade type and size.

2. Prepare the Mower:

– Before installing the dethatching blade, turn off the lawn mower’s engine and disconnect the spark plug wire to prevent accidental starting.

– If necessary, raise the mower deck to its highest position to provide clearance for installing the blade.

3. Remove the Existing Blade:

– If there is a regular cutting blade already attached to the mower, it needs to be removed before installing the dethatching blade.

– Use a wrench or socket set to loosen and remove the nut or bolt that secures the existing blade to the mower’s spindle. Keep the nut or bolt in a safe place for reinstallation later.

4. Attach the Dethatching Blade:

– Align the center hole of the dethatching blade with the spindle on the mower deck.

– Slide the blade onto the spindle, ensuring that the blade’s cutting edges are facing downwards towards the ground.

– Insert the bolt or nut through the center hole of the blade and thread it onto the spindle. Use a wrench or socket set to tighten the bolt or nut securely.

– Follow the manufacturer’s instructions regarding the specific torque or tightening specifications for the blade attachment.

5. Reconnect Spark Plug Wire and Lower the Mower Deck:

– After the dethatching blade is securely attached, reconnect the spark plug wire to the spark plug.

– If you had raised the mower deck earlier, lower it to the desired cutting height for dethatching.

6. Safety Precautions:

– Before starting the lawn mower, ensure that there are no obstructions or objects near the mowing area that could interfere with the dethatching blade.

– Wear appropriate personal protective equipment, such as safety goggles and gloves, to protect yourself during operation.

– Start the lawn mower’s engine and engage the blade according to the mower’s instructions, being cautious of the spinning dethatching blade.

It is important to note that the installation process may vary slightly depending on the specific lawn mower model and manufacturer. Always refer to the mower’s manual and follow the manufacturer’s instructions for safe and proper installation of the dethatching blade.

editor by CX 2023-12-04

China OEM Tiller Cultivator Garden Scarifier Aerator Price Concessions Easy to Operate Welcome Inquiry

Product Description

Please click on my business card to contact us, tell us your needs and provide your WhatsApp/Email.

I will contact you as soon as possible to provide you with preferential prices for your favorite

customized items, without wasting your time!

Kindly note that this is large machine,which should be shipped by sea,pls leave nearest sea port,thanks.

Products Description

The punching machine is composed of a small general-purpose gasoline engine, an

overrunning clutch, a high reduction ratio transmission box and a specially designed

drilling tool, which is suitable for drilling holes on grass and golf courses. It is widely

used in gardens, grasslands, courts and other fields to eliminate soil compaction,

aeration, and permeation, which is conducive to direct water and fertilizer to the lawn

root system.

| Model | ZCKF160 |

| Punch needle diameter | 20mm (Hollow) |

| Punch width | 500mm |

| Punching depth | ≤800mm |

| Number of holes per area | 76 Pieces/M² |

| Working speed | 4.75km/h |

| Work efficiency | 2420m²/h |

| Net weight of the machine | 180KG |

| Size | 1250*800*1257mm |

| Rear axle | Hydrostatic rear axle |

| Way of walking | Self-propelled |

Details Images

The punching machine has the characteristics of small size, light weight, convenient

operation, simple maintenance, low fuel consumption, low noise, easy start-up, high

hole forming efficiency, low operating cost and low price. The punching machine has

a flexible and reasonable design, stable and reliable performance, good working effect

and high efficiency.

lawn aerator,aerator lawn machine,lawn core aerator,lawn aerator shoes,lawn aerator

machine,aerator lawn,petrol lawn aerator,lawn aerator roller,lawn aerator towable,manual

lawn aerators,lawn spike aerator,lawn aerating tine,lawn aerator tool,lawn aerator sandals,

hollow tine lawn aerator,plug lawn aerator,lawn aeration punching machine,lawn aerator

hollow tine,hand lawn aerator,rolling lawn aerator garden,rolling lawn aerator,lawn roller

aerator,aerator spiked lawn roller,aerator lawn machine stand on,lawn corer aerator,lawn

aerator adjustable,cheapest lawn aerator,lawn aerator attachment,aerator lawn tractor

filling core aerator lawn,lawn mower aerator blade,yard butler lawn core aerator,lawn

coring aerator manual grass dethatching turf pl,plug aeration manual lawn coring aerator

4 core,lawn aerator spike,lawn aerator coring,gas lawn aerator,machine lawn aerator,

lawn aerator sandals gardening,petrol lawn coring aerator,lawn aerator pto driven,filling

core aerator lawn tow,garden aerator spiked lawn roller,aerator roller rolling lawn garden

spike,petrol-lawn-aerator,lawn aerator garden, lawn shoe aerators, shoe lawn aerator, lawn

aerator small, lawn roller spike aerator,lawn aerator machine garden, manual lawn coring

aerator, lawn core aerator machine, lawn aerators for grass,lawn aerator machine pro driven,

garden tools outdoor garden lawn aerator

OUR SERVICE

PRE-SALES SREVICE

Inquiry and consulting support

Sample testing support.

View our Factory.

AFTER-SALES SERVICE

Training how to instal the machine, training how to use the machine.

Engineers available to service machinery overseas.

ABOUT WARRANTY

The whole machine is guaranteed for 1 year, free maintenance for life.

Except for improper operation/consumable accessories.

ABOUT INVOICE

The whole network tax increase free shipping.

Take the initiative to contact customer service and provide invoicing information,

apply for invoicing, and post it nationwide.

ABOUT REPAIR

Respond to equipment repair within 10 minutes, and solve the problem within 2 hours;

special faults will be eliminated within 48 hours, and the customer service center will be

called 24 hours a day.

Professional after-sales team, providing after-sales service covering the entire network.

Company Profile

ZheJiang Nature Garden Machinery Co., Ltd. located in HangZhou City, ZheJiang Province. The company

sets R & D , production, sales in one. mainly produces construction machinery, municipal machinery, and

exploration machinery. Construction machinery mainly includes pile driver, pile planter, spiral ground pile

driver, drive mining vehicle, mining dump truck, crawler type truck, truck-mounted excavator, truck-mounted

crane, wheel washing machine, etc. Municipal machinery mainly includes truck-mounted road blowers,

hedge trimmers, leaf suction machine, asphalt spreaders, and resistance pumps;Exploration machinery

mainly includes backpack rigs, core sample rigs, etc.

ZheJiang Nature Garden Machinery Co., Ltd. focuses on product development and improvement, attaches

importance to innovators and product designers, and adjusts production according to the different requirements

of customers. With an experienced and professional team, we have exported our products to many countries

and regions all over the world, especially in the Middle East, Africa and South America. Our products enjoy

a good reputation among our customers. welcome friends from all over the world to contact us and seek

cooperation for mutual benefits.

Certifications

FAQ

Q1. Are you manufacturer or trader?

A:We are a manufacturer of garden machinery and construction machinery. Actually, we produce most of the parts in our own factory for better cost and quality control.

Q2. What is your terms of payment?

A: T/T 30% as deposit, and 70% when machine ready.

Q3. How about your delivery time?

A: Generally, it will take 15 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order. Sometimes we have some in stock.

Q4. Are you interested in dealership with local company?

A: Yes, we are quite interested in this business. We’d like to cooperate with some local partner to sell more machines in local market and supply better service.

Q5. What is your warranty policy?

A: We can supply 1 year warranty or 2000h for our machines. We will provide parts as free within warranty. We can send engineer to customer place if big quality problem. We can provide internet or calling service at any time.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We trust “win-win situation”,we never said our product is best,and maybe our price is not cheapest,but we trust we are your right choice.Because we pay attention to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

Contact us

Add my WhatsAPP for quick response and agency price.

Ivy Lu :

| After-sales Service: | Free Spare Parts Service for Quality Problems with |

|---|---|

| Type: | Micro-Farming Machine |

| Application Field: | Agriculture, Livestock, Aquaculture, Fisheries, Forestry, Golf Course, Football Field |

| Farming Policy: | Dry Cultivating Machinery |

| Power Source: | Gasoline |

| Operation: | Continuous Running Operation, Soil Aeration |

| Samples: |

US$ 1160/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

|

|

|---|

How do you determine when to replace your dethatching blade?

Determining when to replace your dethatching blade is important to ensure effective dethatching and prevent damage to your lawn mower. Here’s a detailed explanation:

1. Inspect the Blade:

– Regularly inspect the dethatching blade for signs of wear, damage, or dullness.

– Look for any visible cracks, chips, or bent tines on the blade.

– Check if the blade has become significantly worn down or if the tines have become excessively blunt.

2. Assess Dethatching Performance:

– Pay attention to the performance of the dethatching blade during use.

– If you notice that the blade is no longer effectively removing thatch or if the dethatching process becomes less efficient, it may be an indication that the blade needs replacement.

– Reduced dethatching performance can be caused by dull or worn-out tines that are no longer able to penetrate and remove thatch effectively.

3. Consider Frequency of Use:

– The frequency of use can also influence when to replace a dethatching blade.

– If you use the dethatching blade frequently or for large-scale dethatching projects, it may wear out faster and require more frequent replacement compared to occasional or smaller-scale use.

4. Follow Manufacturer’s Recommendations:

– Consult the manufacturer’s recommendations and guidelines for the specific dethatching blade you are using.

– Manufacturers often provide guidelines on blade lifespan and replacement intervals based on their product’s design and materials.

– Follow the manufacturer’s recommendations to ensure optimal performance and longevity of the dethatching blade.

5. Err on the Side of Caution:

– If you are unsure about the condition of your dethatching blade or if it has been in use for an extended period, it is better to err on the side of caution and replace the blade.

– Using a worn-out or damaged blade can result in poor dethatching performance, uneven thatch removal, or potential damage to your lawn mower.

– Regularly replacing the dethatching blade when needed will help maintain the quality of your lawn and ensure effective dethatching results.

In conclusion, determining when to replace your dethatching blade involves inspecting the blade for wear or damage, assessing its dethatching performance, considering the frequency of use, and following the manufacturer’s recommendations. It’s important to replace a worn-out or damaged blade to maintain optimal dethatching performance and prevent any potential harm to your lawn mower.

What are the signs that your lawn is in need of dethatching with a blade?

Identifying the signs that your lawn is in need of dethatching with a blade can help you maintain a healthy and vibrant lawn. Here’s a detailed explanation:

1. Thatch Layer Thickness:

– Thatch is the layer of dead grass, debris, and organic matter that accumulates between the grass blades and the soil surface.

– If the thatch layer becomes too thick, it can prevent air, water, and nutrients from reaching the grass roots, leading to poor lawn health.

– One of the signs that your lawn needs dethatching is a thick thatch layer exceeding half an inch in thickness.

2. Reduced Water Infiltration:

– Excessive thatch can hinder water penetration into the soil, causing water to pool on the surface and potentially leading to runoff.

– If you notice that water is not infiltrating the soil properly or is pooling on the lawn after irrigation or rainfall, it may indicate a need for dethatching.

3. Poor Nutrient Absorption:

– Thatch buildup can impede the absorption of nutrients by the grass roots.

– If you have been applying fertilizers regularly but observe that your lawn is not responding with healthy growth and vibrant green color, it could be a sign that your lawn needs dethatching.

4. Increased Pest and Disease Activity:

– Thatch provides a favorable environment for pests, such as insects and rodents, as well as certain lawn diseases.

– If you notice an increase in pest activity or the presence of disease symptoms, dethatching the lawn can help reduce their habitat and improve the overall health of the turf.

5. Poor Air Circulation:

– A thick thatch layer restricts air circulation within the lawn, which can contribute to the development of fungal diseases.

– If you observe patches of discolored or dying grass, particularly in areas with poor air circulation, it may be a sign that dethatching is necessary.

6. Compaction and Sponginess:

– Excessive thatch can contribute to soil compaction and create a spongy or uneven surface on the lawn.

– If you notice that your lawn feels spongy underfoot or exhibits areas of compaction, dethatching can help improve soil aeration and restore a more even surface.

It’s important to note that while these signs indicate a potential need for dethatching, it’s best to assess the condition of your lawn by visually inspecting the thatch layer and considering multiple factors. Additionally, the frequency of dethatching can vary depending on the grass type, climate, and maintenance practices. Consulting with a lawn care professional or following guidelines specific to your region and grass type can help determine the appropriate timing and frequency of dethatching with a blade.

What is a dethatching blade and how is it used?

A dethatching blade is a gardening tool designed to remove thatch from lawns. Thatch is a layer of dead grass, roots, and other organic debris that accumulates between the soil and the healthy grass blades. Here’s a detailed explanation of what a dethatching blade is and how it is used:

1. Definition and Design:

– A dethatching blade is a specialized attachment or accessory that is typically used with a lawnmower or a power rake machine. It consists of a series of sharp, rigid blades or tines arranged in a row.

– The blades or tines of the dethatching blade penetrate the grass and soil, effectively cutting through the thatch layer and lifting it to the surface for removal.

2. Purpose and Benefits:

– The primary purpose of using a dethatching blade is to remove the thatch layer from the lawn. Excessive thatch can prevent air, water, and nutrients from reaching the grassroots, leading to poor lawn health and growth.

– By dethatching the lawn, the grass can better absorb water and nutrients, allowing for improved root development, enhanced overall health, and a more attractive appearance.

3. Usage and Technique:

– Before using a dethatching blade, it is important to ensure that the grass is dry to avoid damaging the turf. Wet grass can be more susceptible to tearing or uprooting.

– The dethatching blade attachment is typically installed on a lawnmower or a power rake machine, following the manufacturer’s instructions.

– When using the dethatching blade, the lawnmower or power rake is moved over the lawn in a systematic pattern, similar to regular mowing, but at a slightly slower pace.

– As the blades or tines rotate or move across the lawn, they cut through the thatch layer, pulling it up and depositing it on the surface in thin strips or clumps.

– After dethatching, the accumulated thatch can be raked or collected and disposed of. Some homeowners may choose to leave a thin layer of thatch behind, depending on the recommendations for their specific grass type.

4. Timing and Frequency:

– Dethatching is typically performed during the growing season when the grass is actively growing and can recover quickly from the process.

– The frequency of dethatching depends on the severity of thatch buildup and the type of grass. In general, it is recommended to dethatch every 1-3 years or as needed.

– Over-dethatching or performing the process too frequently can damage the grass and disrupt the turf’s natural balance.

5. Additional Lawn Care Practices:

– Dethatching is often combined with other lawn care practices, such as aeration and overseeding, to further improve the health and appearance of the lawn.

– Aeration helps alleviate soil compaction and improves the movement of air, water, and nutrients to the grassroots. Overseeding helps introduce new grass varieties and fills in bare patches.

In summary, a dethatching blade is a garden tool used to remove thatch from lawns. It is designed to cut through the thatch layer and lift it to the surface for removal, allowing for improved lawn health and growth.

editor by CX 2023-12-04

China supplier Stainless Steel Durable and Wear-Resistant New Tractor Flip Two-Way Plow Automatic Lift Steering Switch with Logo CZPT Truck Parts CZPT agricultural parts

Product Description

Product Description

| Product Parameters | |

| Quotation | According to your drawing(size, material, thickness, processing content, and required technology, etc) |

| Available Material | Steel, Brass, Zinc alloy , stainless steel, copper, aluminum alloy etc. |

| More Processing | CNC Machining,Plastic Injection,Stamping,Die Casting,Welding,Forging,Silicone And Rubber,Mould Making,etc |

| Surface Treatment | Powder Coating, Anodizing, Brushing, Polishing, Electric-plating, Pvd Coating, Hot Dip Galvanizing, E-coating, Tin Plating, Nickel,Plating, Chrome Plating, Dacromet, Enamel Coating etc. |

| OEM | Silkscreening,Engraving,Laser Printing,Cut-out making, Custom Packaging Box etc. |

| Application | All kinds of cars,machinery,home appliance,electronic products,electric appliance,stationery,computers,power switches,miniature switcher,architecture,commodity and A/V equipment,hardware and plastic molds,sports equipment and gifts,and more. |

| Manufacturing Type | Precision Machining, CNC Milling, CNC Lathe Turning, Tapping, Drilling, Grinding, Wie EDM, Stamping, Deep Drawing, CNC Punching, Laser Cutting, CNC Bending, Die Casting, Welding etc |

| Industries Served | Aerospace, Automotive, Agriculture, Construction, Electrical, Electronic, Home Appliance, Medical,Marine, Machinery, Furniture, Food, Lighting,Telecommunication etc |

| File Format | Solidworks,Pro/Engineer,Auto CAD,PDF,JPG,DXF,IGS,STEP |

| QC | 100% Strict Inspection For Every Processing |

| One-stop Service | Custom Design, Fabrication, Assembly And Delivery |

| Packing | Packing according to your requirements |

Detailed Photos

Company Profile

Packaging & Shipping

Our Advantages

FAQ

Q: When can I get reply after send inquiry?

A: 1. All inquiries will be replied within 2 hours on Chinese working time.

2. Our call phones standing by any calls at any time.

Q: How long can I get samples ?

A: Generally samples can be sent to you within 7 working days after product drawing confirmed by both side.

Q: What file format can you accept for my products/design?

A: 1. We can accept varies format, igs, step, stp, jpg,pdf, dwg, dxf and so on.

Q: If I don’t have drawing, how can I get sample ?

A: If you don’t have any drawing,you can send us your sample, we will scan it and make 2D and 3D drawing first, then make sample for you.

Q: What are common materials that you use in projects?

A: Aluminum,Stainless Steel, Carbon Steel, Copper, Plastics etc.

Q: What’s your MOQ(minimum order quantity)

A: Different products have different MOQs, Welcome to send us trial order firstly.

Q: What kind of payment do you accept?

A: Welcome paid by T/T, L/C, Paypal, Western Union.

Q:what is your payment method?

A:Paypal, Alibaba, 30% value of T/T in advance and other 70% balance before shipping. For small order less than1000USD, would suggest you pay 100% in advance to reduce the bank charges.

| Application: | Fastener, Auto and Motorcycle Accessory, Machinery Accessory |

|---|---|

| Standard: | GB, EN, China GB Code, JIS Code |

| Surface Treatment: | Anodizing |

| Production Type: | Mass Production |

| Machining Method: | CNC Milling |

| Material: | Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Agricultural Parts

Agricultural machinery, also known as agricultural machinery, is any mechanical device or structure used in agriculture . It includes hand tools, tractors and countless other farm implements. Agricultural machinery can be divided into two categories: power tools and hand tools. Some of the most common types of agricultural equipment are listed below. Each of these categories includes parts used to repair, maintain, and operate a specific piece of equipment or machinery. To learn more about agricultural machinery, please visit the Manufacturers and Suppliers section of our website.

Agricultural Machinery

Agricultural machinery parts are critical to the overall operation of a farm or ranch. Replacement parts are essential if your equipment is not functioning as expected. CZPT’s consumables experts are ready to help you find the right replacement parts for your equipment. You can rely on our knowledgeable staff to provide you with fast and accurate replacement services. If your agricultural machinery needs replacement parts, please contact us for assistance.

Key drivers of the agricultural machinery market include high global demand for food, rapid crop production, access to resources, and availability of credit. Agricultural machinery is mainly manufactured in Europe, the United States, Japan and China. Overall, we expect the agricultural machinery market to exceed $118 billion by 2025. Additionally, agricultural machinery OEM components are expected to grow at a CAGR of 3.6% over the next five years.

Agricultural machinery accessories include accessories and accessories other than tractor accessories. Plows loosen the soil and kill surface vegetation, fertilizer spreaders apply fertilizer evenly, rakes agitate the soil, and seeders sow seeds. Other accessories include balers, which collect materials and bundle them into management packs. Transplanters are used to transplant plants from one location to another. It must be properly maintained to maximize its useful life.

Farm machinery accessories can be found in all types of farming. From sowing to harvesting, farm machinery equipment is necessary to help farmers in various agricultural activities. Without mechanization, farming would not be as profitable as it is today. In Iran, CZPT produces agricultural machinery parts including harrows, tillers, grain refiners, spinning machines and threshers. You can also find farm machinery accessories for sale through these companies.

A well-known brand in the field of agricultural machinery is CZPT. Parts can be found for CZPT and CZPT models. The company also produces replacement parts for many different models. The company’s extensive dealer network spans more than 160 countries. PDF also supplies agricultural machinery parts for brands such as Ford and CZPT. If you are looking for reliable quality and cost-effective agricultural machinery, we can get the parts you need from these brands.

Agricultural Equipment

Growing population and demand for equipment drive the demand for agricultural equipment in Asia. In countries with limited land such as India, low-paying agricultural jobs are not enough for many farmers. At the same time, Australia has a large amount of agricultural land, but the reduction of agricultural labor has led to the increasing mechanization and integration of agricultural production. This, in turn, has fueled a surge in demand for Australian agricultural products in Asia, particularly in China and India.

Tractor transplanter is a common agricultural equipment. Tractors pull on these machines, which dig holes and put plants into the holes. A cultivator is another type of agricultural equipment that tills the soil and controls weeds. Smaller operations often use a cultivator. Large plastic farms, on the other hand, need to invest in cladding, using a series of wheels to lay down a layer of plastic.

Agricultural machinery is widely used. For example, tractors can carry heavy agricultural attachments such as haymakers and grain turbines. Farm equipment also helps farmers prepare soil for growing and harvesting large quantities of crops. It also helps transport food to other regions for processing. These machines make farming easier and more efficient. With all these benefits, it’s no wonder so many people engage in farming as a profession. The world needs food and agriculture, and agricultural equipment is an integral part of the process.

Agricultural equipment operators use heavy agricultural machinery every day. They inspect the equipment and make minor repairs to keep it running smoothly. They also monitor the working environment and working conditions around the equipment. Depending on the field, agricultural equipment operators can operate a variety of agricultural equipment, load and unload products, and even harvest crops. These workers may spend most of the year working outdoors, which can take a long time. The average workweek for an agricultural equipment operator is approximately 18 hours.

Agricultural equipment operators often gain practical experience on the job. Some jobs in the industry may require a high school diploma, and students without a high school diploma can work on farms to learn the skills needed for the position. The industry requires employees to be properly trained and certified to operate equipment safely. AWS certification is highly recommended. All Associate of Applied Science in Agricultural Production Systems include core business and management courses applicable to the agricultural industry.

Agricultural machinery manufacturers

Agricultural machinery manufacturers produce agricultural implements such as tractors and combines for agricultural purposes. The production of these machines increases the productivity and efficiency of farmers around the world. These machines and parts increase the quality and quantity of crop production while reducing labor costs. They also help improve soil fertility. It’s important to choose the right type of machine for your farm because not all farm machinery is the same. There are many high-quality agricultural machinery manufacturers in China, whose prices are competitive with the local market prices.

The growth of the agricultural machinery market is mainly driven by the growing global food demand. Agricultural equipment manufacturers are investing in precision-based technologies, which allow them to build better agricultural machines. In addition, OEM parts manufacturers focus on the safety, quality and continuous improvement of agricultural machinery parts. With the shift in focus, the agricultural machinery market is expected to make great strides in the coming years. Along with these improvements, the demand for agricultural machinery OEM parts is expected to grow at an annual rate of over 3%.

CZPT Group: This agricultural machinery manufacturer has more than 20 overseas service centers around the world. The company is committed to providing excellent customer service and provides a warranty on all of its products. CZPT Machinery’s space parts are easily available at their service center. Shandong CZPT Heavy Industry International, a Chinese agricultural machinery manufacturer, was established in 1998 and is headquartered in Weifang City, Shandong Province.

Although the agricultural machinery industry is growing, the market is still affected by the economic downturn. The COVID-19 pandemic has put pressure on farming operations, who may forgo buying expensive equipment. Private investment in industrial equipment is also falling and is expected to decline further in 2020 and 2021. On the other hand, aftermarket agricultural machinery parts are tailored for an exact fit and outperform OEM parts.

Agricultural Machinery Suppliers

Agricultural Machinery Suppliers have a wide variety of products. From large farm machines to small ones, you’ll find it all in one place. In addition to providing first-class machinery, agricultural machinery suppliers can also provide you with spare parts. Shandong Heavy Industry International, for example, is China’s largest agricultural machinery maker, with annual sales of $9 billion. The company is headquartered in Weifang, Shandong and has been operating for more than six years.

Most farm equipment consists of hundreds of parts. For example, a typical tractor has more than 1,700 parts. Manufacturers have been shifting to just-in-time delivery of parts and raw materials. While the system works for predictable supply chains, it can break down when one component fails. Therefore, the best way to avoid problems and maximize profits is to get a list of Indian agricultural machinery suppliers through a dedicated marketplace.

Therefore, there are many suppliers of agricultural machinery. Some of the biggest names in the industry include CZPT and CZPT, both of which employ thousands of people. CZPT also offers a complete line of walk-behind and riding mowers, as well as log splitters and snow blowers. In addition, the German-made CZPT tractor line is being launched in Brazil. Finally, some smaller agricultural machinery enterprises produce and sell agricultural machinery.

In the next decade, the global agricultural machinery market will grow moderately. But in the short term, crop prices are expected to fall, which will negatively affect agricultural income and the agricultural machinery market. Experts predict that this will affect the demand for agricultural machinery. These factors will continue to influence the market and help farmers make better decisions. However, no single factor can guarantee that the agricultural machinery industry will not be affected by economic changes.

In addition to tractors, other types of agricultural machinery are also widely used for agricultural purposes. Tractors are the most common type of agricultural machinery and include rotary tillers, power tillers, subsoilers and trowels. Other equipment used for planting includes planters, planters and irrigation systems. Some specialized equipment includes sprinkler systems, micro sprinklers, and soil spray technology.

editor by CX 2023-11-21

China OEM Sealed Hb Hardened Gear Reducer Prevents Contamination Extending Lubricant and Parts Life shoup agricultural parts

Product Description

Product Description: High-Power HB Hardened Gear Reducer

Customized Solutions, Superior Performance

We take pride in introducing the High-Power HB Hardened Gear Reducer, a power transmission solution designed to meet your unique requirements and deliver top-tier performance. We understand that each application is distinct, so we consider factors such as connection size, operating environment, required power, and speed to provide you with tailor-made gear reducers, ensuring a perfect fit without any waste.

Key Features:

- High Efficiency: Our gear reducers feature advanced design and manufacturing techniques to ensure high efficiency and CZPT performance. What’s more, we’ve introduced a brand-new online product configurator that requires no prior gear reducer knowledge. With just 3 simple steps, you can configure your product and generate detailed 3D drawings.

- Exceptional Load Capacity: In real-world operating conditions, our gear assemblies must withstand the highest loads and substantial axial and radial forces. To meet this challenge, we offer compact and robust drive solutions that meet the stringent demands of continuous operation, ensuring maximum operational reliability even under intermittent loads.

- Versatile Options: Our product range provides extensive options to ensure the gear reducer optimally suits your application needs. These options include baseplate mounting, torque shaft support, oil cooling connections, and suitability for temperatures as low as -40°C.

Advantages:

- Highest Power Density: Compact, lightweight, yet powerful, suitable for a wide range of high-power requirements.

- High Efficiency and Maximum Performance: We strive for outstanding performance and high efficiency to ensure your operations remain at their peak.

- Outstanding Quality and Reliability: Our gear reducers are meticulously designed and manufactured to meet the highest standards of quality and reliability.

- High Overload Capacity: Twice the rated torque’s high overload capacity ensures readiness for any challenge.

- Modularity: Our design is highly modular, allowing for easy customization to meet different application requirements.

Application Areas:

- Rolling Mills: Used in metalworking and manufacturing industries for rolling mills, providing excellent power transmission.

- Sugar Mills: In the sugarcane industry, it can be used for various mechanical applications, processing and handling sugarcane.

- Central Drives: Serving as a central drive unit, it provides robust power transmission and precise control.

- Plate Feeders: Used for material conveyance and handling, ensuring stable torque transmission and reliability.

- Vertical Grinder Drive Units: Applied in mining and ore processing sectors, providing high-performance drive solutions.

- Mobile Drive Units: Applicable to various vehicles and industrial machinery, offering exceptional power transmission performance.

No matter how diverse your application areas, the High-Power HB Hardened Gear Reducer is your trusted power transmission partner. We are committed to delivering exceptional performance and reliability, catering to all your needs.

Please let me know where you would like me to send the Word document containing this product description.